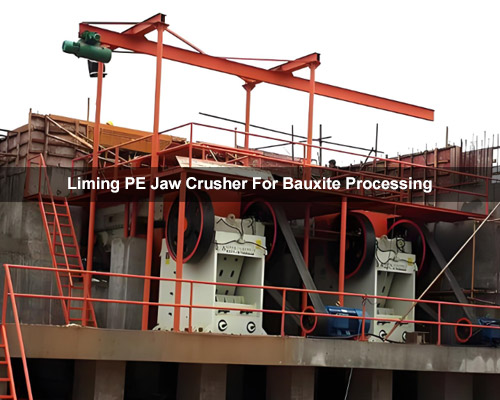

Liming PE Jaw Crusher For Bauxite Processing

December 24, 2025

Summary:This article details the technical advantages of Liming's PE Jaw Crusher, its specific application in raw bauxite processing, and a comprehensive guide for global buyers to optimize their crushing lines.

In the global mining and aggregate industry, selecting the right equipment for the first stage of reduction is critical. Liming Heavy Industry, a leading manufacturer of mineral processing equipment, offers the world-renowned PE jaw crusher. Whether you are building a stationary plant or a mobile line, a high-quality jaw crusher ensures that downstream equipment operates at peak efficiency. The liming crusher is engineered to handle the toughest materials, from hard granite to abrasive bauxite, providing a stable and high-output solution for global operators.

Industry Pain Points and the Liming Solution

Quarry owners and mining contractors often face challenges such as high wear costs, frequent downtime for maintenance, and inconsistent final product sizes. These issues directly erode the Return on Investment.

The PE jaw crusher from Liming Heavy Industry is designed to overcome these hurdles. By utilizing high-strength manganese steel for jaw plates and a heavy-duty eccentric shaft, our jaw crusher offers superior durability and a longer service life compared to standard models. Our design emphasizes a deep crushing chamber, which increases the feed capacity and ensures high-efficiency reduction.

Specialized Application: Raw Bauxite Processing

For clients involved in aluminum production, understanding the bauxite process in detail is essential. Bauxite is often found with varying degrees of hardness and moisture content, requiring a robust primary stage.

Bauxite Process in Detail

Raw bauxite processing typically begins with primary crushing. The liming crusher effectively reduces large bauxite boulders into manageable sizes (usually below 100-150mm) for further grinding or secondary crushing.

- Step 1: Feeding – Raw bauxite is fed via a vibrating feeder into the PE jaw crusher.

- Step 2: Primary Crushing – The moving jaw plate exerts pressure against the fixed jaw, breaking the ore through compression.

- Step 3: Screening – The crushed bauxite is then sent to a vibrating screen to separate the desired fractions.

Technical Specifications of Liming PE Jaw Crusher

Our PE jaw crusher series covers a wide range of capacities and feed sizes to suit various project scales.

| Model | Feed Opening (mm) | Max Feed Size (mm) | CSS Adjustment (mm) | Capacity (t/h) |

|---|---|---|---|---|

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 |

Installation and Maintenance Guide

To maximize the lifespan of your liming crusher, proper installation and maintenance are paramount.

- Foundation: Ensure the concrete foundation is at least 3 times the weight of the jaw crusher to absorb vibration.

- Lubrication: Use high-quality lithium-based grease for the toggle plate and eccentric shaft bearings every 8 hours of operation.

- Jaw Plate Rotation: To ensure even wear, swap the fixed and moving jaw plates when the lower teeth are worn down by 50%.

5 Common Q&A

1. What is the maximum hardness the PE jaw crusher can handle?

The liming crusher can process materials with a compressive strength of up to 320MPa, including granite, basalt, and iron ore.

2. How do I adjust the discharge opening (CSS)?

The CSS is adjusted via a mechanical wedge system or gaskets located at the back of the jaw crusher, allowing you to control the size of the output material.

3. Is the PE series suitable for mobile plants?

Yes, smaller models like the PE-250×400 or PE-600×900 are frequently integrated into our wheel-mounted mobile crushing plants.

4. How often should I replace the jaw plates?

This depends on the abrasiveness of the material (e.g., quartz will wear plates faster than limestone). Regular inspection every 100-200 operating hours is recommended.

5. Why choose Liming Heavy Industry over other brands?

Our PE jaw crusher uses high-end bearings (SKF or equivalent) and a reinforced frame, providing higher reliability and a better ROI for long-term projects.

The PE jaw crusher from Liming Heavy Industry remains the industry standard for primary crushing. Its simple structure, ease of maintenance, and massive crushing ratio make it the ideal choice for raw bauxite processing and general stone quarrying. By choosing a liming crusher, you are investing in a machine that delivers consistent performance under the most demanding conditions.