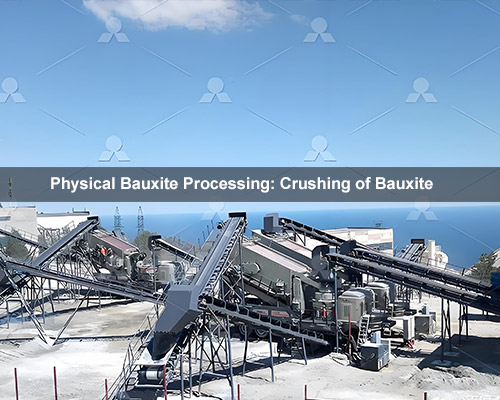

Physical Bauxite Processing: Crushing and Grinding of Bauxite

December 10, 2025

Summary:An authoritative guide on the bauxite crushing and grinding process, featuring Liming Heavy Industry's equipment, technical specifications, and maintenance advice.

Bauxite is the world’s primary source of aluminum, serving as the critical raw material for the Bayer process. However, before chemical extraction can occur, efficient physical bauxite processing is mandatory. For mining investors and plant operators, optimizing the bauxite ore crushing and grinding process is not just about reducing particle size; it is about maximizing recovery rates and minimizing operational costs. As a leading manufacturer, Liming Heavy Industry provides comprehensive solutions tailored to the unique properties of bauxite ore.

1. Understanding the Material: Characteristics of Bauxite

To design an efficient crushing of bauxite circuit, one must understand the ore’s physical traits. Bauxite typically varies from soft, earthy material to hard, dense rock. Key characteristics influencing processing include:

- Hardness: Ranges from 1 to 3 on the Mohs scale for earthy types, but can reach 6+ for diasporic bauxite.

- Moisture Content: High moisture can cause clogging in traditional crushers.

- Abrasiveness: Silica content can increase wear on crusher liners.

2. Industry Pain Points in Bauxite Processing

Many operators face significant challenges during raw bauxite processing:

- Equipment Blocking: High humidity bauxite often sticks to the crushing cavity.

- Uneven Particle Size: Inconsistent crushing leads to inefficiencies in the grinding stage.

- High Energy Consumption: Outdated grinding mills consume excessive electricity, eating into profit margins.

3. The Solution: Liming Heavy Industry’s Process Flow

We address these pain points with a scientifically designed bauxite process in detail. The typical flowchart includes:

Stage 1: Primary Crushing

Large raw bauxite boulders are fed into a primary crusher. For this, the PE Series Jaw Crusher is the industry standard, offering a deep crushing cavity and high reduction ratio.

Stage 2: Secondary Crushing

The output is transferred to a secondary crusher. Depending on the hardness, we recommend the HPT Multi-cylinder Hydraulic Cone Crusher. Its lamination crushing principle ensures a uniform product shape, which is crucial for the subsequent grinding phase.

Stage 3: Grinding (Pulverizing)

This is the critical step for the Bayer process. The material is ground to a fine powder (usually 200 mesh). The LM Vertical Ore Mill integrates drying, grinding, classifying, and transporting, making it the ideal choice for high-capacity bauxite processing.

4. Technical Specifications & Recommended Equipment

Below is a comparison of Liming Heavy Industry’s flagship equipment suitable for bauxite:

| Equipment Type | Model Recommendation | Capacity (t/h) | Key Advantage for Bauxite |

|---|---|---|---|

| Primary Crusher | PE-900×1200 Jaw Crusher | 220 – 450 | High stability, handles large feed sizes. |

| Secondary Crusher | HPT300 Cone Crusher | 160 – 400 | Hydraulic protection clears the cavity if sticky bauxite blocks it. |

| Grinding Mill | LM170K Vertical Mill | 10 – 45 | High drying capacity for wet bauxite; small footprint. |

5. Application Case Study

Project Location: Guinea

Material: Bauxite

Capacity: 500 TPH

Configuration: PE Jaw Crusher + HST Cone Crusher + Vibrating Screen.

Customer Feedback: “Liming Heavy Industry provided a solution that handled our high-silica bauxite effectively. The automated control system of the HST Cone Crusher reduced our downtime by 30% compared to our previous equipment.”

6. Buying Guide: Bauxite Crushing and Grinding Machine Price

Investors often ask: What is the bauxite crushing and grinding machine price? The cost is variable and depends on several factors:

- Capacity Requirements: A 100 TPH plant costs significantly less than a 1000 TPH plant.

- Configuration: A mobile crushing station offers flexibility but has a higher initial investment than a fixed plant.

- Automation Level: Fully PLC-controlled systems (like our HPT series) command a premium but offer lower long-term labor costs.

To get a precise quote, please contact our engineering team with your specific output requirements.

7. Installation and Maintenance Guidelines

To ensure longevity:

- Foundation: Ensure a reinforced concrete foundation to absorb vibration.

- Lubrication: Regularly check the oil station of the HPT Cone Crusher and LM Mill.

- Wear Parts: Monitor the wear of jaw plates and grinding rollers. Replace them promptly to maintain product quality.

8. Frequently Asked Questions (Q&A)

Q1: Can your machines handle bauxite with high moisture content?

A: Yes. For crushing, we can adjust the jaw settings. For grinding, the LM Vertical Mill introduces hot air to dry the material while grinding, handling moisture up to 15%.

Q2: What is the lifespan of the wear parts?

A: It depends on the bauxite’s silica content. However, Liming uses high-manganese steel and proprietary alloy materials to extend lifespan by 20-30% compared to standard market parts.

Q3: Do you provide installation services abroad?

A: Yes, Liming Heavy Industry has a global service team to assist with on-site installation, commissioning, and operator training.

Q4: How does the HPT Cone Crusher improve the bauxite process?

A: It uses inter-particle crushing (lamination), which produces more cubic shapes and fewer needles/flakes, reducing the workload on the grinding mill.

Q5: How can I get a layout design for my plant?

A: Send us your topography map and capacity requirements. Our engineers will provide a CAD or 3D design within 24-48 hours.

Conclusion

Optimizing the physical bauxite processing line requires a balance of robust machinery and smart engineering. From the initial crushing of bauxite to the final fine powder generation, Liming Heavy Industry offers the technology to ensure high efficiency and low operational costs. If you are looking for a reliable partner and a competitive bauxite crushing and grinding machine price, contact us today to customize your production line.