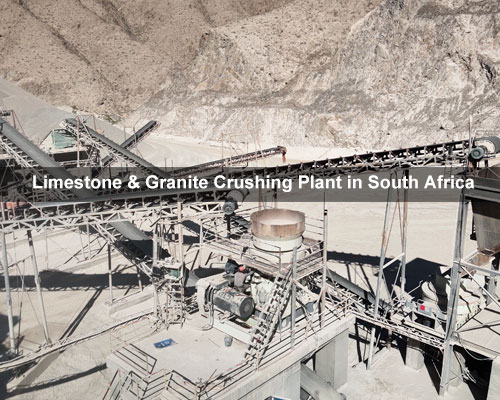

100 TPH Limestone & Granite Crushing Plant in South Africa

Client Profile

- Location: South Africa

- Material: Limestone & Granite

- Production Capacity: 100 tons per hour (TPH)

- Application: Concrete and road construction aggregates

- Final Products: 0-5mm manufactured sand (M-sand),5-10mm, 10-20mm, 20-31.5mm aggregates

Our client, a leading construction company in South Africa, required a reliable 100 TPH stone crushing plant to process both limestone and granite for infrastructure projects.

Project Overview

The client needed a comprehensive crushing solution that could handle hard granite (high abrasiveness) and soft limestone (easy to crush but requires shaping) while maintaining high productivity and low operational costs.

Primary Goals:

- Achieve 100 TPH efficiency

- Produce well-graded 0-5mm, 5-15mm, 15-31.5mm aggregates

- Ensure low energy consumption & minimal wear costs

Challenges

- Material Hardness Variance – Granite (~250 MPa compressive strength) requires strong crushing force, while limestone (~80 MPa) needs fine shaping.

- High Wear-Resistant Demand – Granite’s abrasiveness demands durable equipment.

- Stable Output Requirement – The plant needed consistent 100 TPH performance without downtime.

- South African Harsh Climate – Dust control, heat resistance, and corrosion prevention were critical.

Solution by Liming Heavy Industry

Our engineers designed a three-stage crushing & screening configuration to maximize efficiency:

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X125

- Input Size: ≤650mm

- Output Size: ≤200mm

- Role: Coarse crushing for raw limestone & granite

- Advantages:

- Deep crushing chamber for high throughput

- Optimized jaw plate reduces wear in granite processing

- Hydraulic adjustment for quick discharge setting changes

2. Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT200

- Input Size: ≤200mm

- Output Size: ≤40mm

- Role: Medium-fine crushing for shaping aggregates

- Advantages:

- Multi-cylinder design for uniform particle size

- Laminated crushing principle extends wear parts lifespan

- Automated hydraulic system ensures stable discharge

3. Tertiary Crushing & Sand Making – VSI6X Sand Maker

- Model: VSI6X1150

- Input Size: ≤40mm

- Output Size: 0-5mm (high-quality artificial sand)

- Role: Fine shaping for premium sand production

- Advantages:

- Impeller optimization for high sand yield (≥60%)

- Four-port rotor design reduces wear and maintenance

- Low noise & vibration for South Africa’s environmental standards

Supporting Equipment:

- Vibrating Feeder (GZD1100×4200) – Ensures steady feeding

- Vibrating Screen (3YK2160) – Separates multiple aggregate sizes

- Belt Conveyors – Facilitates smooth material transfer

Technical Highlights

- Smart PLC Control System – Automated adjustment for production optimization

- Energy-Efficient Motors – Reduces power consumption by 15%+

- Dust Suppression System – Complies with South African EPA regulations

- Wear-Resistant Alloy Parts – Extends service life in granite crushing

Project Results

- 100 TPH achieved with a 95% uptime rate

- High-quality aggregates: 0-5mm (sand), 5-15mm (concrete), 15-31.5mm (road base)

- Low operating costs due to reduced wear and automation

- Environmental compliance with minimal dust and noise

Client Feedback

“Liming Heavy Industry’s C6X Jaw Crusher, HPT Cone Crusher, and VSI6X Sand Maker have transformed our quarry operations. The system runs efficiently, and the final aggregate quality meets international standards!”

– Production Manager, South African Construction Group