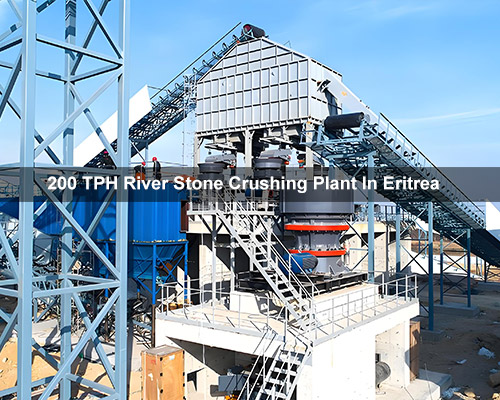

200 TPH River Stone Crushing Plant In Eritrea

Client Overview

Our client in Eritrea operates a large-scale construction and quarrying business, focusing on producing high-quality sand and aggregates for infrastructure projects. Facing increasing demand for construction materials, they sought a reliable crushing solution capable of processing 200 tons of river stone per hour into uniform-sized aggregates.

Project Background

River stones are hard-wearing materials, requiring durable and efficient crushing equipment. The Eritrean customer needed a complete sand production line that could withstand abrasive conditions while delivering high capacity and consistent particle size distribution.

Challenges

- Material Hardness: River stones are tough, requiring wear-resistant crushing machines.

- High Capacity Demand: The plant needed stable operation at 200TPH without frequent breakdowns.

- End Product Quality: The aggregates had to meet strict standards for construction use.

Solution: Liming Heavy Industry’s Sand Production Line

Our engineers designed a tailored crushing and screening plant featuring primary jaw crushing, secondary cone crushing, and sand shaping to maximize productivity and particle shape.

Equipment Configuration

- Vibrating Feeder (GZD1100×4200)

- Ensures smooth and controlled feeding into the crusher.

- Prevents raw material jams and enhances crusher efficiency.

- C6X Jaw Crusher (C6X125) – Primary Crushing

- Handles large river rocks (≤750mm) effortlessly with deep crushing chamber.

- High crushing ratio minimizes bottlenecking.

- HPT Hydraulic Cone Crusher (HPT300) – Secondary Crushing

- Ensures finer and more uniform discharging (≤45mm).

- Fully automatic hydraulic adjustment reduces downtime.

- VSI6X Sand Maker (VSI6X1150) – Tertiary Crushing & Shaping

- Produces high-quality manufactured sand with excellent gradation.

- Enhances cubical shape for superior concrete mixtures.

- S5X Vibrating Screen (S5X2460-3) – Screening & Grading

- Efficiently separates aggregates into multiple fractions (0-5mm, 5-10mm, 10-20mm, 20-45mm).

- Heavy-duty screen decks improve longevity in abrasive operations.

- Belt Conveyors (B6X)

- Facilitates seamless material transfer between crushing stages.

Technical Highlights

- Automated Lubrication System: Ensures smooth operation of crushers and screens.

- Dust Suppression Integration: Reduces airborne particles for environmental compliance.

- Energy-Efficient Motors: Lowers operational costs while maintaining high output.

Project Results

- Achieved 200TPH production capacity consistently.

- Final sand & aggregates met ASTM and ISO standards.

- Reduced maintenance costs through wear-resistant liners & automated monitoring.

Client Feedback

“Liming Heavy Industry’s crushing plant exceeded our expectations. The C6X Jaw Crusher and HPT Cone Crusher handled our tough river stones effortlessly, and their VSI6X Sand Maker produced excellent-quality sand for our concrete projects.” – Site Manager, Eritrea Mining Co.