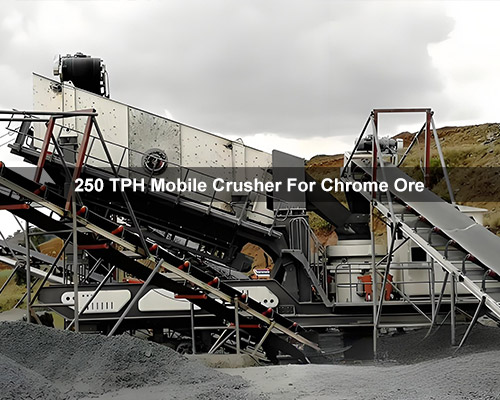

250 TPH Mobile Crusher For Chrome Ore Processing in South Africa

Client Overview

A leading mining company in South Africa specializing in chromium ore extraction sought a high-capacity, flexible crushing solution to process raw ore efficiently. Requirements included mobility, reliability, and high throughput (250 tons per hour).

Project Summary

Liming Heavy Industry provided a turnkey mobile crushing solution, delivering a NK Series Mobile Crushing Station tailored for chromium ore processing. The project maximized crushing efficiency, reduced operational costs, and ensured optimal material sizing for downstream processing.

Challenges

- Hard & abrasive chromium ore requiring durable wear-resistant crushing equipment.

- Mobility needed due to remote mining sites and frequent relocation.

- Strict output requirement (250 tons per hour) to meet processing demands.

- Dust & noise control for compliance with environmental regulations.

Solution: Liming Heavy Industry’s NK Series Mobile Crushing Station

The turnkey mobile crushing plant included:

1. NK Mobile Jaw Crusher – Primary Crushing

- Model: NK96 (C6X Jaw Crusher Configuration)

- Capability: High-strength crushing for raw chromium ore ≤750mm.

- Advantages: Optimized crushing chamber, hydraulic adjustment, and deep cavity design for maximum efficiency.

2. NK Mobile Cone Crusher – Secondary Crushing (Fine Crushing)

- Model: NK300 (HPT Multi-cylinder Hydraulic Cone Crusher)

- Capability: Produces precisely shaped end products (0-30mm).

- Advantages: Multi-cylinder hydraulic system ensures consistent output and protects against overloading.

3. Vibrating Screen & Return System

- Model: S5X Vibrating Screen

- Function: Accurate screening for different fractions (0-5mm, 5-10mm, 10-30mm).

- Advantage: High screening efficiency, minimal blockages.

4. Dust Suppression & Control System

- Feature: Integrated water spray system reduces dust emissions.

- Compliance: Meets South Africa’s environmental regulations.

Technical Highlights

- Fully mobile & quick setup: Relocates easily, reducing site downtime.

- Automation & remote monitoring: Real-time operational tracking via Liming’s smart control system.

- Wear-resistant materials: Extends component lifespan in abrasive chromium ore conditions.

Project Results

- Output Achieved: 250+ TPH consistently.

- Crushed Ore Quality: Well-graded 0-30mm end product for smelting use.

- Reduced Operating Costs: Minimal maintenance and fuel-efficient design.

Client Feedback

“Liming’s mobile crushing station exceeded our expectations. The NK Series setup allowed us to process hard chromium ore efficiently, with minimal downtime. The support team was responsive, ensuring smooth operation.” – Mining Operations Manager, South Africa