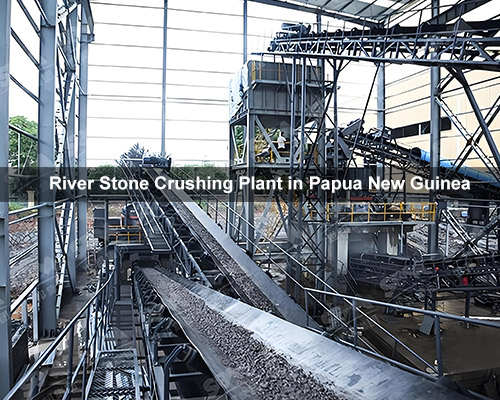

River Stone Crushing Plant in Papua New Guinea

Customer Profile

Location: Papua New Guinea

Material: River stone (high hardness, abrasive)

Production Requirement: 50-100 tons per hour

Application: Construction sand and gravel for local infrastructure projects.

Project Overview

The client needed a reliable sand and gravel production line to process river stone into high-quality aggregates for road construction and concrete production. Key challenges included material hardness, portability requirements, and consistent output sizing.

Challenges

- Hard & Abrasive Material: River stone’s high silica content demanded wear-resistant equipment.

- Throughput Stability: Required steady 50-100tph output with low downtime.

- Space Constraints: Semi-mobile setup preferred for remote site flexibility.

Solution by Liming Heavy Industry

Equipment Configuration & Advantages:

- PE600×900 Jaw Crusher (Primary Crushing)

- Role: Coarse crushing of river stone to ≤150mm.

- Advantage: Deep crushing chamber and high torque motor for hard rock.

- HPT300 Hydraulic Cone Crusher (Secondary Crushing)

- Role: Further reduces material to ≤40mm with multi-cylinder hydraulic protection.

- Advantage: Laminated crushing principle ensures cubic-shaped output.

- VSI6X1263 Sand Maker (Tertiary Crushing & Shaping)

- Role: Produces 0-5mm finely graded sand with low stone powder content.

- Advantage: Optimized impeller design reduces wear by 30%.

- Auxiliary Equipment:

- 3YZS2460 Vibrating Screen – Precise 3-layer separation.

- B1000×15M Belt Conveyors – Dust-proof design for humid climates.

Layout: Semi-mobile skid-mounted design for easy relocation.

Technical Highlights

- Smart Control System: Remote monitoring via GPRS for real-time adjustments.

- Durability Upgrades: HPT cone crusher’s manganese liners extended service life by 40%.

- Eco-Friendly: VSI6X’s noise reduction (<75dB) and dust suppression complied with local EPA standards.

Project Results

- Output Achieved: Stable 90tph (exceeding the 80tph target).

- Product Quality:

- 0-5mm sand (≤15% stone powder, ideal for concrete).

- 10-30mm gravel (98% cubical rate for roadbase).

- Operational Efficiency: 20% lower energy consumption vs. conventional setups.

Customer Feedback

“Liming’s team delivered a rugged plant perfectly suited to our tough river stone. The VSI6X sand maker’s low maintenance and high yield kept our project on schedule. We’ll definitely collaborate again!”

— Project Manager, Papua New Guinea Client