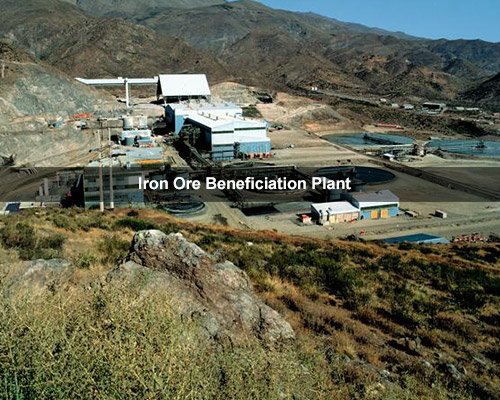

Iron Ore Beneficiation Plant

November 13, 2025

Summary:This article provides a comprehensive overview of the iron ore beneficiation plant, including the process flow, technology, typical process steps, and crusher equipment used. It highlights the key benefits of our machines in beneficiation processes, offering real-world case studies and solutions for common challenges.

Introduction to Iron Ore and Beneficiation

Iron ore is a crucial raw material for steel production, with various types including hematite, magnetite, limonite, and siderite. These ores contain different iron concentrations and require specialized processing to achieve the quality needed for steelmaking. Iron ore beneficiation is the process of increasing iron content while reducing impurities like silica, alumina, and phosphorous to enhance the ore’s economic value.

As a leading manufacturer of mineral processing equipment, Liming Heavy Industry provides comprehensive solutions for iron ore beneficiation plants, delivering advanced technology and reliable equipment for efficient and profitable operations.

Iron Ore Beneficiation Process Flow Chart

The iron ore beneficiation process flow chart provides a visual representation of the sequential steps involved in transforming raw iron ore into a concentrate suitable for steel production. A typical process includes:

Typical Iron Ore Beneficiation Process Flow

- Crushing: Primary, secondary, and tertiary crushing to reduce ore size

- Screening: Classification of ore into different size fractions

- Grinding: Further size reduction to liberate iron minerals from gangue

- Beneficiation: Separation using magnetic separation, gravity concentration, or flotation

- Dewatering: Removal of water from the concentrate and tailings

This typical iron ore beneficiation process can be customized based on specific ore characteristics and customer requirements. The goal is to maximize iron recovery while minimizing operational costs.

Material Introduction and Processing Flow

Iron ores vary significantly in composition, structure, and physical properties. Hematite (Fe₂O₃) and magnetite (Fe₃O₄) are the most commercially important iron ores. Hematite typically contains 50-65% iron, while magnetite contains 45-70% iron. The beneficiation approach depends on the ore type and its inherent characteristics.

Complete Processing Stages

- Primary Crushing: Jaw Crusher (like our PE Series) reduce run-of-mine ore to manageable sizes

- Secondary Crushing: Cone Crusher (such as our HPT Series) further reduce particle size

- Grinding: Ball Mills pulverize the ore to liberate iron particles

- Beneficiation: Magnetic separators, spiral classifiers, and flotation cells separate iron from gangue

- Dewatering: Thickeners and filters remove moisture from the final product

Technology of the Iron Ore Beneficiation Plant

The technology of the iron ore beneficiation plant has evolved significantly, with modern plants incorporating advanced automation and process control systems. At Liming Heavy Industry, we integrate cutting-edge technologies to optimize performance and efficiency:

Advanced Crushing Technology

Our crusher feature hydraulic adjustment systems, wear protection, and optimized crushing chambers for maximum efficiency.

Intelligent Process Control

Automated monitoring and control systems ensure optimal operation parameters and consistent product quality.

Energy-Efficient Grinding

Our grinding mills are designed for minimal energy consumption while achieving superior size reduction.

We continuously innovate to improve the setup of the iron ore beneficiation plant, focusing on reducing operational costs, enhancing recovery rates, and minimizing environmental impact.

Crushing Equipment Application Range

Liming Heavy Industry offers a comprehensive range of crushing equipment suitable for various stages in iron ore beneficiation plants. Our equipment handles different ore types and processing requirements with exceptional reliability and performance.

| Equipment Type | Model Examples | Application in Iron Ore Beneficiation | Capacity Range (t/h) |

|---|---|---|---|

| Jaw Crusher | PE Series, PEW Series | Primary crushing of large iron ore | 50-1500 |

| Cone Crusher | HPT Series, HST Series | Secondary and tertiary crushing | 60-1100 |

| Impact Crusher | CI5X Series, PFW Series | For medium-hard ores | 70-1300 |

| Mobile Crushing Plant | K Series | Flexible and mobile processing | 90-800 |

Equipment Capacity and Types

Selecting the right equipment with appropriate capacity is crucial for an efficient iron ore beneficiation plant. Our equipment range covers various capacities to match different production requirements:

Crushing Equipment Specifications

- PE Series Jaw Crusher: Capacity up to 1500 t/h, feed opening up to 1500×1300mm

- HPT Multi-cylinder Hydraulic Cone Crusher: Capacity up to 1100 t/h, with automated control system

- CI5X Impact Crusher: Capacity up to 1300 t/h, with heavy-duty rotor design

- MW Series Micro Powder Mill: For ultrafine grinding applications

- Ball Mill: Various sizes available for grinding operations

We provide comprehensive technical support to help you select the optimal equipment configuration for your specific needs and capacity requirements.

Common Challenges and Solutions

Iron ore beneficiation operations face several challenges that can impact productivity and cost-effectiveness. Here are common issues and our recommended solutions:

Abrasive Ore Wear

Challenge: Iron ore is highly abrasive, causing rapid wear on equipment components.

Solution: Our equipment features wear-resistant materials and specialized lining systems that extend service life and reduce maintenance downtime.

Variable Ore Characteristics

Challenge: Fluctuations in ore composition and hardness affect process stability.

Solution: We design flexible systems with adjustable operating parameters and incorporate advanced control systems to maintain optimal performance despite feed variations.

Water and Energy Consumption

Challenge: Traditional beneficiation processes consume significant amounts of water and energy.

Solution: Our designs incorporate water recycling systems and energy-efficient equipment to minimize resource consumption and operational costs.

Case Study: Successful Iron Ore Beneficiation Project

Project Overview

A major mining company in South Africa needed to upgrade their existing iron ore beneficiation plant to process 2,000 tons per day of hematite ore with a feed grade of 45% Fe. The goal was to achieve a final concentrate grade of at least 64% Fe with maximum iron recovery.

Solution Provided

Liming Heavy Industry designed and supplied a complete beneficiation system including:

- Primary crushing with PE1200×1500 Jaw Crusher

- Secondary crushing with two HPT300 Cone Crusher

- Grinding circuit with Ball Mills

- Magnetic separation system

- Dewatering equipment

Results Achieved

- Final concentrate grade: 65.2% Fe

- Iron recovery rate: 92.5%

- Capacity: Exceeded target at 2,200 t/day

- Energy consumption: 15% lower than industry average

This project demonstrates our capability to deliver comprehensive solutions that exceed performance expectations while optimizing operational costs.

Why Choose Liming Heavy Industry

With decades of experience in mineral processing equipment manufacturing, Liming Heavy Industry offers distinct advantages for your iron ore beneficiation plant:

Proven Expertise

Over 30 years of experience in designing and manufacturing crushing and beneficiation equipment.

Comprehensive Solutions

From single machines to complete turnkey plants, we provide end-to-end solutions.

Advanced Technology

Continuous R&D investment ensures our equipment incorporates the latest technological innovations.

Global Support

Comprehensive after-sales service and technical support network across multiple countries.

Customized Designs

We tailor solutions to match your specific ore characteristics and production requirements.

Quality Assurance

All equipment manufactured to international quality standards with rigorous testing procedures.

Optimize Your Iron Ore Beneficiation Operations

An efficient iron ore beneficiation plant is crucial for maximizing productivity and profitability in today’s competitive mining industry. With the right equipment, technology, and process flow, you can significantly improve recovery rates and product quality while controlling operational costs.

Liming Heavy Industry has the expertise, equipment, and technology to help you design and implement the optimal typical iron ore beneficiation process for your specific requirements. Contact us today to discuss how we can enhance your iron ore beneficiation operations.