Quartz Stone Crusher Suppliers

January 16, 2026

Summary:This article provides a comprehensive guide for investors looking for professional quartz stone crusher suppliers. We analyze industry pain points like high wear and energy consumption, showcasing Liming Heavy Industry's advanced solutions and real-world project success.

In the global industrial sand and glass manufacturing market, the demand for high-purity quartz is skyrocketing. However, finding the right quartz stone crusher suppliers involves more than just comparing prices. It requires a partner who understands the abrasive nature of quartz and the technical challenges of high-load production.

Solving the 3 Core Pain Points in Quartz Crushing

As a veteran in the mining machinery industry, Liming Heavy Industry has identified three recurring challenges that plague quartz processing plants. Here is how we solve them:

1. High Wear and Frequent Maintenance

Quartz has a Mohs hardness of 7, making it extremely abrasive. Standard crushers often suffer from rapid wear of liners and blow bars.

The Solution: Our HST Series Single Cylinder Hydraulic Cone Crusher utilizes high-manganese steel alloys and a unique crushing chamber design that maximizes “inter-particle crushing,” significantly reducing direct contact between the stone and the metal liners.

2. High Energy Consumption vs. Low Yield

Many suppliers offer outdated machines that consume massive amounts of electricity without hitting the target throughput.

The Solution: The VSI6X Series Vertical Shaft Impact Crusher features a “four-opening” impeller design that increases throughput by 30% compared to traditional models while optimizing the power-to-crush ratio.

3. Dust Control and Environmental Compliance

Quartz dust (silica) is a major health and environmental hazard.

The Solution: Our integrated crushing plants are equipped with pulse dust collectors and sealed conveyor systems to ensure your operation meets the strictest environmental standards.

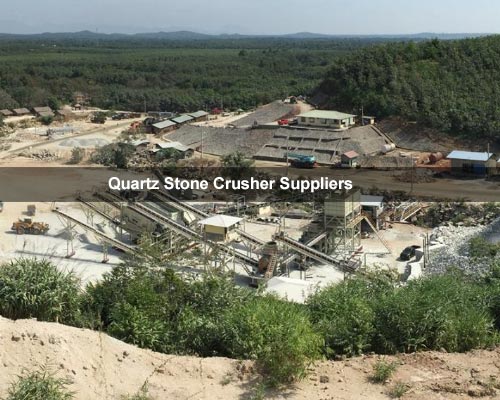

Social Proof: Liming’s Global Footprint

Nothing speaks louder than a successful operation. Below is a snapshot of one of our high-performing quartz processing sites:

| Project Location | Binh Duong, Vietnam |

|---|---|

| Processed Material | High-Purity Quartz Stone |

| Capacity | 200 – 250 Tons Per Hour (t/h) |

| Core Equipment Configuration | PE-750×1060 Jaw Crusher, HST250 Cone Crusher, VSI6X1150 Sand Maker |

| End Product | 0-5mm, 5-10mm, 10-20mm high-quality aggregate and sand. |

20-Year Engineer’s Advice: Don’t Just Buy a Machine, Buy a Process

“In my 20 years of commissioning plants across the globe, the biggest mistake I see investors make is focusing solely on the initial purchase price of the crusher. With quartz, the Total Cost of Ownership (TCO) is what matters. A cheaper machine from an unverified supplier will cost you triple in spare parts and downtime within the first year. Always ask your supplier for a wear-part life expectancy report based on your specific material hardness. At Liming, we don’t just sell you a box; we design a flow that minimizes friction and maximizes profit.”— Senior Project Engineer, Liming Heavy Industry

Frequently Asked Questions (FAQ)

Which type of crusher is best for quartz?

For quartz, a combination of a Jaw Crusher (Primary) and a Hydraulic Cone Crusher (Secondary) is ideal due to the material’s hardness. For fine sand making, a VSI Crusher is essential to achieve a cubical shape.

How do I verify the reliability of quartz stone crusher suppliers?

Check for ISO and CE certifications, ask for recent project case studies in your region, and evaluate their after-sales service network. A reputable supplier like Liming provides on-site installation and technician training.

What is the average lifespan of wear parts when crushing quartz?

Depending on the silica content, high-quality cone liners should last between 800 to 1,200 hours. We offer optimized alloys to extend this window by up to 20%.

Can Liming provide customized crushing solutions?

Yes. We provide bespoke EPC (Engineering, Procurement, and Construction) services, tailoring the equipment configuration to your specific raw material, capacity requirements, and site topography.

Conclusion: Partner with a Leader in Quartz Crushing

Choosing between quartz stone crusher suppliers is a decision that will define your plant’s profitability for the next decade. Liming Heavy Industry combines 30+ years of manufacturing excellence with cutting-edge technology to ensure your quartz production is efficient, sustainable, and high-yielding.