Stone Crusher Machine Price in Kenya

February 3, 2026

Summary:This case study addresses the "price" query by showcasing a real-world example in Kenya (Nairobi). Instead of just listing prices (which vary), it demonstrates the value of a specific Liming configuration (Jaw + Cone) for processing hard basalt, common in Kenyan infrastructure projects.

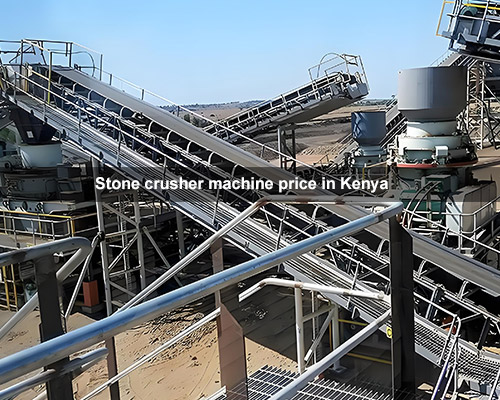

With major infrastructure projects like the Standard Gauge Railway (SGR) and highway expansions continuing across East Africa, the demand for high-quality aggregate is at an all-time high. For quarry owners in Nairobi, Kisumu, and Mombasa, finding the right balance between cost and quality is critical. Many investors often ask about the stone crusher machine price in Kenya, fearing that top-tier equipment might be out of budget.

However, the initial price tag is only part of the story. High maintenance costs and downtime can quickly turn a “cheap” machine into a financial burden. Liming Heavy Industry offers a solution that balances competitive factory-direct pricing with durability. In this case study, we examine a 100TPH basalt crushing project in Kenya to show how the right investment leads to long-term profitability.

Project Profile: 100TPH Basalt Crushing Line in Nairobi

A construction materials supplier based near Nairobi contacted Liming Heavy Industry. They needed to upgrade their aging equipment to meet the strict aggregate standards for local road construction projects.

The Challenge

- Hard Raw Material: The quarry contained Basalt (Traprock), which is very hard and abrasive. Their previous impact crusher was suffering from rapid wear, driving up operating costs.

- Budget Constraints: The client was sensitive to the stone crusher machine price in Kenya and needed a solution that was affordable yet capable of handling hard rock.

- Output Requirements: They needed 0-6mm, 6-10mm, and 10-20mm aggregates with a cubical shape for concrete mixing.

The Liming Solution

To address the hardness of the stone and the client’s budget, Liming engineers designed a two-stage crushing line. We replaced the high-wear impact crusher with a durable hydraulic cone crusher, which significantly reduced the long-term “price” of operation.

Equipment Configuration:

| Stage | Equipment Model | Purpose |

|---|---|---|

| Primary Crushing | PE600×900 Jaw Crusher | Handles large basalt boulders; classic robust design ensures low failure rate. |

| Secondary Crushing | CS Cone Crusher (Spring) | Selected for its low entry price and effectiveness in crushing hard rock. |

| Screening | 3YZS1848 Vibrating Screen | Efficiently separates the final aggregate into three required sizes. |

| Transport | B500 Belt Conveyors | Connects the system for a continuous flow. |

Analysis: Price vs. Performance

The client initially hesitated due to shipping and import duties impacting the final stone crusher machine price in Kenya. However, the results spoke for themselves:

1. Reduced Wear Cost

By switching to a Cone Crusher for the secondary stage, the client reduced the frequency of replacing wear parts from once a week to once a month. This saving alone offset the initial equipment cost within the first year.

2. Localized Support

Liming Heavy Industry has established strong connections in East Africa. We provided on-site installation guidance and trained local Kenyan operators, ensuring the machine ran at peak efficiency without needing expensive external consultants.

3. High Resale Value

Because Liming equipment is recognized globally, the machinery retains value. If the project ends, the equipment can be resold in the local market at a competitive price.

Frequently Asked Questions (FAQ)

What factors influence the stone crusher machine price in Kenya?

The price depends on capacity (TPH), the type of stone (hard vs. soft), and configuration (mobile vs. stationary). Import duties, taxes (VAT), and shipping costs from China to the Port of Mombasa also play a significant role in the final landed cost.

Does Liming have agents or offices in Kenya?

Liming Heavy Industry has a dedicated sales team for the East African market and cooperates with local partners. We frequently visit Nairobi to provide after-sales support and technical upgrades for our clients.

Is it better to buy a mobile or stationary crusher for a Kenyan quarry?

If you own the quarry and have a long-term license, a stationary plant is more cost-effective. However, if you are a contractor moving between road projects, a mobile crusher is worth the higher initial price due to the savings in installation and transport time.

Invest in Quality for Long-Term Gain

When researching the stone crusher machine price in Kenya, it is essential to look beyond the sticker price. A reliable system that handles hard basalt with minimal downtime is the true key to profitability.

Liming Heavy Industry is committed to supporting Kenya’s infrastructure growth with durable, high-yield crushing solutions. Our engineers are ready to design a flow chart that fits your specific budget and terrain.