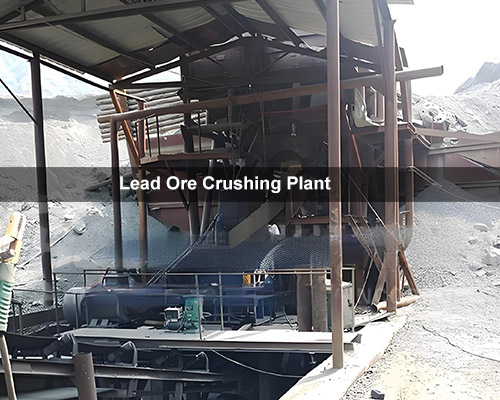

Lead Ore Crusher Liming Shanghai

September 4, 2025

Summary:This article provides an authoritative overview of lead ore crushing solutions offered by Liming Heavy Industry, covering technology, capacity, process, and real-world results.

As a premier manufacturer of crushing and mining equipment, Liming Heavy Industry (Shanghai) offers robust and efficient solutions for lead ore processing. This article delves into the specifics of lead ore crushing, highlighting our technological advancements and proven machinery designed to maximize your operation’s productivity and profitability.

Understanding Lead Ore

Lead ore, primarily found as galena (lead sulfide), is a crucial raw material for batteries, radiation shielding, and construction. Its processing begins with crushing the raw ore to liberate the valuable minerals from the waste rock, a stage where efficiency is paramount for downstream recovery rates.

Application Scope of Our Lead Ore Crushers

Our lead ore crushers from Liming Heavy Industry are engineered for a wide range of applications, including:

- Primary crushing in large-scale open-pit and underground mining operations.

- Secondary and tertiary crushing circuits in stationary and mobile processing plants.

- Integration with feeding, screening, and conveying systems for turnkey solutions.

Technology and Innovation in Crushing

At Liming Heavy Industry, we integrate cutting-edge technology into our crushers. Our machines feature:

- Advanced Crushing Chambers: Optimized for lead ore’s characteristics to achieve higher reduction ratios and minimize over-crushing.

- Intelligent Control Systems: PLC-based automation for real-time monitoring and adjustment of crusher parameters, ensuring optimal performance and protecting the equipment from damage.

- Wear-Resistant Materials: Critical components are made from high-quality, abrasion-resistant alloys, significantly extending service life in abrasive ore conditions.

Capacity and Types of Crushers We Offer

We provide a complete portfolio of crushers to handle any lead ore processing need, with capacities ranging from 50 TPH to over 1000 TPH.

- Jaw Crusher (PE Series & JC Series): Ideal for primary crushing. Models like PE600×900 and JC110 handle large feed sizes with high capacity.

- Cone Crusher (HPT Series & HST Series): Perfect for secondary and tertiary crushing. The HPT300 multi-cylinder hydraulic cone crusher offers exceptional productivity and fine product shape.

- Impact Crusher (CI5X Series & PFW Series): Excellent for producing a well-shaped cubical product. The CI5X1320 is a powerful option for medium to hard ores.

Typical Lead Ore Crushing Process

- Primary Crushing: Run-of-mine lead ore is fed into a Jaw Crusher (e.g., PE750×1060) to reduce the ore to a manageable size, typically below 200mm.

- Secondary Crushing: The crushed material is then conveyed to a Cone Crusher (e.g., HPT200) for further size reduction.

- Tertiary Crushing (if needed): For finer product requirements, an Impact Crusher (e.g., CI5X1220) or another cone crusher can be used.

- Screening: crushed material is screened by our Vibrating Screen (S5X Series) to separate the product into various size fractions, with oversize material sent back for further crushing.

Common Challenges and Our Solutions

- Challenge: Abrasive Wear. Lead ore can be highly abrasive, causing rapid wear on crusher parts.

Solution: Our crushers use replaceable liners and mantles made from super high manganese steel or TIC insert alloys, offering 2-3 times longer lifespan than standard materials. - Challenge: Throughput Fluctuations. Inconsistent feed can lead to crusher clogging and downtime.

Solution: Our intelligent hydraulic adjustment and clearing systems, standard in HPT and HST cone crushers, allow the crusher to handle tramp iron and unstoppable feed changes automatically, reducing downtime by up to 70%.

Case Study: Increased Output for a Nigerian Lead-Zinc Mine

Client: A leading mining company in Nigeria.

Challenge: The existing crushing line struggled with low availability (75%) and could not achieve the target output of 250 TPH due to frequent breakdowns and high wear part consumption.

Solution: Liming Heavy Industry supplied a new crushing circuit centered around our JC110 Jaw Crusher for primary crushing and two HPT300 Cone Crushers for secondary and tertiary crushing.

Results:

- Average throughput increased to 280 TPH, exceeding the target.

- Availability soared to 94% due to the reliability of our equipment.

- Wear part costs were reduced by 40% annually.

- The client achieved a full ROI on the new plant within 14 months.

Why Choose Liming Heavy Industry?

- Proven Equipment: Our crushers are tested in our own state-of-the-art laboratory and proven in thousands of real-world installations.

- Full-Service Support: We offer end-to-end support, from plant design and equipment supply to installation, commissioning, and after-sales service.

- Global Parts Network: Ensure you get genuine spare parts quickly, minimizing operational disruptions.

- Customized Solutions: We don’t just sell machines; we provide solutions tailored to your specific ore characteristics and production goals.

Conclusion and Call to Action

Choosing the right lead ore crusher is a critical decision that directly impacts your bottom line. Liming Heavy Industry’s combination of robust machinery, innovative technology, and global expertise makes us the ideal partner for your processing needs.

Ready to optimize your lead ore crushing operation? Contact our expert team at Liming Heavy Industry today for a free consultation and a customized quotation. Let us help you build a more profitable and efficient plant.