Limestone Crushing Machinery and Quarry Plant Design

September 16, 2025

Summary:Liming Heavy Industry's complete guide to limestone crushing machinery and quarry plant design. Discover jaw crushers, cone crushers, impact crushers, with capacities up to 8898 t/h, and optimized quarry layouts for efficiency, cost reduction, and sustainable mining practices.

Limestone is a fundamental raw material in construction, cement production, agriculture, and various industrial processes. Efficiently processing this resource requires robust crushing machinery and scientifically designed quarry plans. As a leading manufacturer of mineral processing equipment, Liming Heavy Industry provides high-performance crushing solutions and comprehensive quarry design support to help operators maximize productivity, reduce operational costs, and ensure sustainable operations.

1. Classification and Production Capacity of Limestone Crushing Machinery

Selecting the right crushing equipment is crucial for achieving desired product specifications and output rates. Here’s a breakdown of the primary types of limestone crushing machinery and their typical production capacities:

| Equipment Type | Primary Function | Typical Production Capacity | Key Characteristics |

|---|---|---|---|

| Jaw Crusher | Primary Crushing | Up to 1435 t/h | Deep crushing chamber, large crushing ratio |

| Cone Crusher | Secondary Crushing | Up to 2181 t/h | Multi-cylinder hydraulic system |

| Impact Crusher | Secondary/Tertiary Crush | Varies by model | Good product shape, high reduction ratio |

| Mobile Crushing Plant | Flexible Crushing | 70-760 t/h | Integrated feeding, crushing, screening |

1.1. Jaw Crushers: The Primary Crushing Workhorse

Jaw crushers are ideal for the primary crushing of large limestone rocks, reducing them to manageable sizes for further processing. Their robust construction and high capacity make them perfect for tough quarry conditions.

- Production Capacity: Modern jaw crushers can achieve capacities up to 1435 tons per hour (t/h).

- Application: Best for initial size reduction of raw limestone extracted from the quarry face.

1.2. Cone Crushers: Precision Secondary and Tertiary Crushing

For secondary and tertiary crushing, cone crushers are highly efficient, especially for producing fine aggregates and uniform product size.

- Production Capacity: Advanced multi-cylinder hydraulic cone crushers can achieve impressive throughputs, with capacities up to 2181 t/h.

- Application: Ideal for intermediate and final crushing stages to achieve high-quality, cubical end products.

1.3. Impact Crushers: Shaping and Cubicizing Output

Impact crushers are excellent for secondary crushing, producing uniformly shaped aggregates ideal for construction and road building. They offer high reduction ratios and superior product quality.

- Application: Suitable for producing precisely shaped end products from limestone.

1.4. Mobile Crushing Plants: Flexibility and Mobility

Mobile crushing stations offer unparalleled flexibility, combining crushing and screening functions on a single chassis. They are perfect for quarries with multiple pit locations or limited space.

- Production Capacity: Depending on the configuration, capacities typically range from 70 to 760 t/h.

- Power Options: Many modern units feature hybrid diesel-electric power systems, reducing energy consumption.

- Application: Highly suitable for remote sites, decentralized quarry points, and projects requiring frequent relocation.

2. Optimized Quarry Plant Design for Limestone Operations

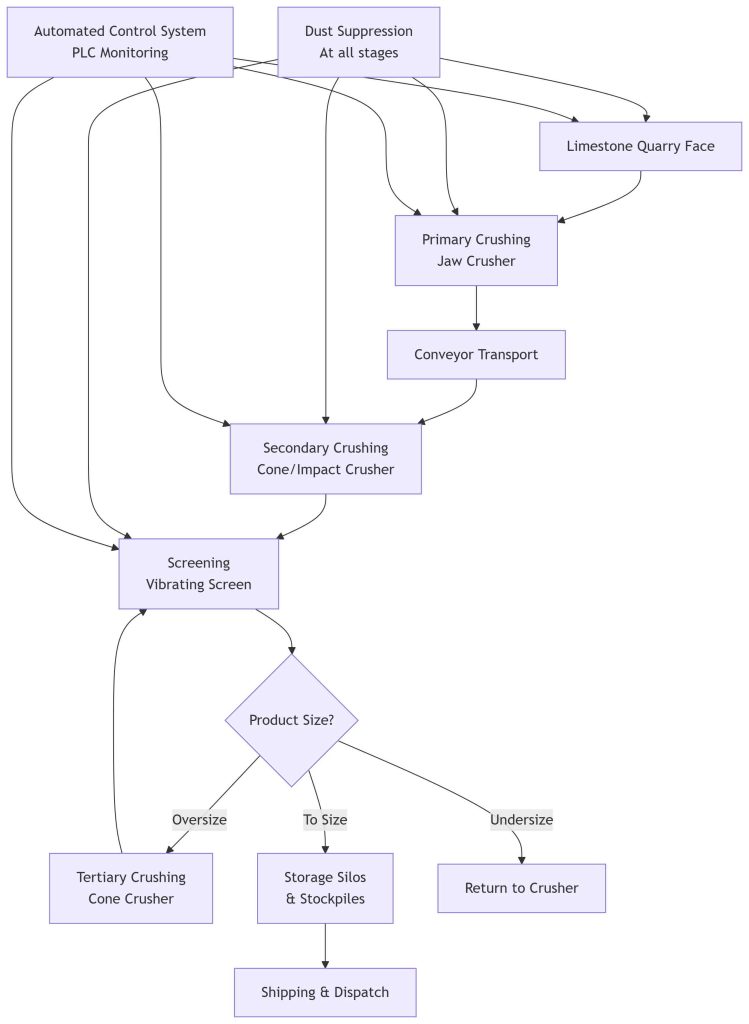

A well-designed quarry layout is fundamental for operational efficiency, safety, and environmental management. It involves strategic planning of the entire site to minimize material handling costs, reduce downtime, and ensure a smooth flow of material from excavation to shipment.

2.1. Core Considerations in Quarry Plant Design

- Resource Evaluation & Geological Assessment: Conduct thorough core drilling and analysis to understand the limestone deposit’s quality, volume, hardness, and structural composition.

- Site Planning and Layout: The arrangement of crushing stages, haul roads, and storage areas is critical.

- Environmental and Safety Compliance: Integrate dust suppression systems, noise control measures, and comprehensive water management plans from the initial design phase.

- Automation and Control Systems: Implement modern control systems for real-time monitoring of equipment parameters, allowing for adaptive adjustments and predictive maintenance.

2.2. Key Quarry Design Components and Best Practices

- Haul Road Optimization: Design wide, stable haul roads with proper grading to facilitate safe and efficient transportation.

- Crushing Plant Layout: Position the primary crusher as close to the excavation face as feasible to reduce haulage costs.

- Dust Control Strategies: Deploy comprehensive dust suppression at all transfer points, crusher inlets/outlets, and screening decks.

- Rehabilitation and Ecological Integration: Plan for concurrent rehabilitation and final land use, designing final slopes for stability.

3. Integrated Solutions from Liming Heavy Industry

At Liming Heavy Industry, we offer more than just machinery; we provide end-to-end solutions tailored to your specific quarry conditions and production goals.

- Customized Equipment Configuration: We help you select the optimal combination of crushers and screens based on your limestone’s characteristics.

- Turnkey Project Support: From initial site survey to plant layout design, equipment supply, and operator training.

- Focus on Sustainability: Our designs and equipment prioritize energy efficiency and incorporate advanced environmental controls.

- Global Service Network: Ensure continuous operation with our reliable after-sales support.

4. Conclusion: Building a Sustainable and Profitable Future

Maximizing productivity in limestone processing hinges on the seamless integration of the right crushing machinery with a rationally designed and optimized quarry layout. By adopting modern, high-capacity equipment and embracing holistic planning, quarry operators can significantly enhance efficiency, reduce operating costs, and ensure long-term, sustainable growth.

Partner with Liming Heavy Industry to leverage our expertise in equipment manufacturing and quarry design. Let us help you build a more efficient, profitable, and environmentally responsible limestone operation.