Limestone Quarry Production Line Design PDF

June 19, 2025

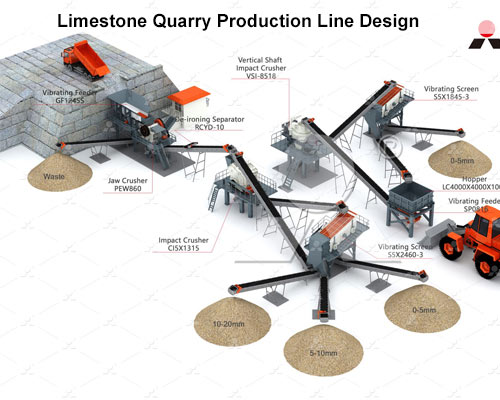

Summary:Designing an efficient limestone quarry production line requires precision engineering and robust equipment. As a leading manufacturer of mining crushing equipment for 25+ years, Liming Heavy Industry provides proven solutions for high-yield limestone processing.

Introduction

Designing an efficient limestone quarry production line requires professional equipment selection and optimal layout planning. Liming Heavy Industry offers complete solutions with our high-performance crushing and screening equipment, tailored for limestone processing operations.

Key Components of Limestone Quarry Production Line

1. Primary Crushing Stage

- Recommended Equipment: PEW European Jaw Crusher

- Handles large raw limestone blocks (≤1200mm)

- High crushing ratio and low energy consumption

2. Secondary Crushing Stage

- Recommended Equipment: HST Single Cylinder Hydraulic Cone Crusher

- For medium-fine crushing (output size: 20-50mm)

- Intelligent automation system for stable operation

3. Tertiary Crushing/Sand Making Stage

- Recommended Equipment: VSI6X Sand Making Machine

- Produces high-quality manufactured sand (0-5mm)

- Cubic-shaped end products for construction applications

4. Screening & Grading

- Recommended Equipment: S5X Vibrating Screen

- Multi-layer screening for precise classification

- Heavy-duty design for quarry environments

Production Line Layout Design Considerations

- Material Characteristics: Hardness, moisture content, and feeding size

- Output Requirements: Target capacity (e.g., 200-500 TPH) and product gradation

- Space Optimization: Compact arrangement to minimize conveyor lengths

- Dust Control: Proper sealing and dust suppression systems

Why Choose Liming Heavy Industry’s Solutions?

- 30+ years of quarry equipment manufacturing experience

- Customized designs with 3D layout simulations

- Energy-efficient crushing technology (up to 30% power saving)

- Comprehensive after-sales service network

Related Articles