What Are the Types of Gold Mining Crushers?

May 9, 2025

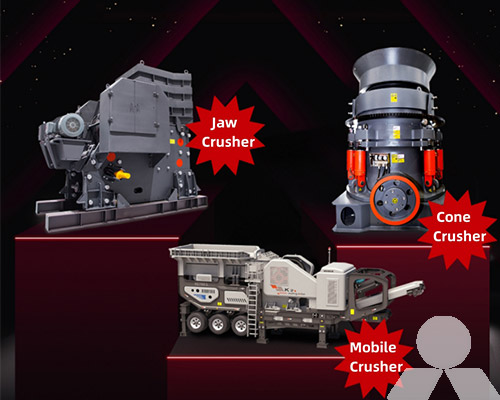

Summary:Jaw crushers are ideal for primary crushing, while cone crushers work best for secondary and tertiary crushing. Impact crushers are great for shaping gold-bearing material.

Gold mining operations require specialized crushing equipment to process ore efficiently. Choosing the right crusher is essential for optimal production and cost-effectiveness. This guide explores the main types of crushers used in gold mining operations worldwide.

Primary Crushing Equipment for Gold Mining

1. Jaw Crushers

- Function: First stage crushing of large gold-bearing rocks

- Models: PE600×900, PEW1100, PE500×750

- Features:

- High crushing ratio (up to 6:1)

- Simple structure with easy maintenance

- Handles feed sizes up to 600mm

- Suitable for all types of gold ores

2. Gyratory Crushers

- Best for: Large-scale gold mining operations

- Capacity: Handles over 1,000 tons/hour

- Advantages:

- Higher capacity than jaw crushers

- Continuous crushing action

- Lower maintenance requirements

Secondary Crushing Solutions

1. Cone Crushers (Various Types)

- HST Hydraulic Cone Crushers:

- Automated adjustment and protection

- Used in Vietnam tungsten/gold operations

- Models: HST100(S2), HST250S2/H2

- Spring Cone Crushers:

- CSB160, CSD160 models in Zimbabwe gold mines

- Simpler structure than hydraulic versions

2. Impact Crushers

- Applications:

- Gold ore with lower abrasiveness

- Final shaping of aggregates

- Examples:

- PF1010 impact crusher in Malaysian gold operations

- Produces more cubic-shaped particles

Tertiary Crushing and Finer Reduction

VSI Crushers (Vertical Shaft Impactors)

- Gold Recovery Benefits:

- Liberates gold from finer particles

- “Rock-on-rock” crushing minimizes wear

- Output: 0-10mm gold-bearing material

High-Pressure Grinding Rolls (HPGR)

- Emerging Technology:

- Energy efficient fine grinding

- Increases gold exposure for recovery

Mobile Crushing Solutions for Gold Mining

Advantages of Mobile Crushers:

- Rapid deployment to new sites

- Ideal for small-medium gold operations

- Eliminates need for fixed infrastructure

- Examples in Guyana’s alluvial gold projects

Selection Considerations

Key Factors When Choosing Gold Mining Crushers:

- Ore characteristics (hardness, moisture content)

- Required throughput capacity

- Feed and product size requirements

- Mobility needs (fixed vs. portable)

- Downstream recovery methods

The choice between jaw, cone, impact crushers or mobile units depends on your specific gold mining operation’s requirements. Many successful operations combine multiple crusher types in stages to achieve optimal size reduction while maintaining efficiency and wear part longevity.

For gold mining projects requiring customized crushing solutions, consult with mineral processing specialists to design the most effective crushing circuit for your ore type and production goals.