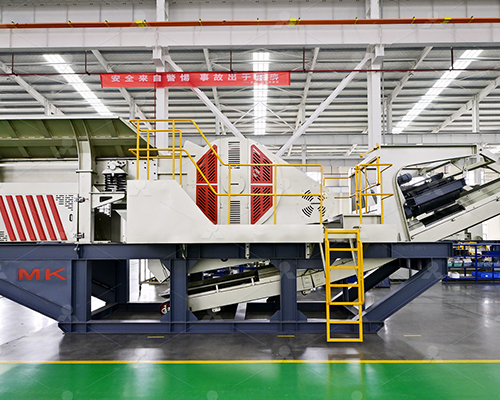

MK Crushing and Screening Plant

As a pioneer in integrated mineral processing solutions, Henan Liming Heavy Industry proudly presents the MK Crushing and Screening Plant – a modular, high-capacity system engineered to deliver seamless multi-stage crushing, screening, and material handling for the most demanding mining and construction projects. Combining flexibility with industrial-scale productivity, the MK series redefines efficiency in aggregate and ore processing.

Product Overview

The Liming MK Crushing and Screening Plant is a fully customizable modular system that integrates primary crushing, secondary/tertiary grinding, precision screening, and automated material conveying into a cohesive production line. Designed for both fixed and semi-mobile installations, its plug-and-play modules allow rapid deployment and scalability, making it ideal for greenfield projects or capacity expansion in existing operations.

Key Features

- Modular Innovation

- Pre-assembled steel-framed modules (crushers, screens, conveyors) for fast on-site assembly.

- Expandable design supports capacity upgrades without downtime.

- Smart Production Flow

- Centralized PLC system synchronizes crusher RPM, feeder speed, and screen vibration for optimal throughput.

- RFID-enabled component tracking for predictive maintenance.

- Energy Optimization

- Regenerative power recovery system reduces energy consumption by 25-40%.

- Hybrid power options (diesel/electric/solar) for off-grid operations.

- Dust & Noise Control

- Closed-loop dust suppression with HEPA filtration (PM2.5 < 10μg/m³).

- Soundproof enclosures maintain noise levels below 75 dB(A).

- Heavy-Duty Engineering

- Reinforced wear liners with Ceramic-Tough® coating for abrasive materials.

- Earthquake-resistant structural design (up to 8.0 magnitude).

Processing Capacity & Materials

- Materials Processed:

Iron ore, copper ore, gold-bearing rock, granite, limestone, demolition concrete. - Feed Size:

Primary: Up to 1,500 mm | Tertiary: Up to 300 mm - Output Range:

0-3mm (ultra-fine sand), 3-60mm (graded aggregates), or customized metallurgical sizes. - Production Capacity:

500-2,000 tonnes/hour (configurable across 6 standard MK models).

Applications

- Mega quarry operations requiring continuous 24/7 production

- Metal mine processing plants (copper, gold, iron ore)

- High-speed rail and highway construction material bases

- Coastal reclamation projects with large-scale aggregate demand

- Industrial byproduct recycling (slag, coal gangue)