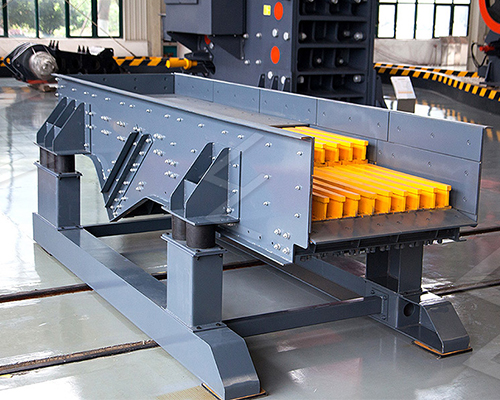

GF Series Vibrating Feeder

Henan Liming Heavy Industry Science & Technology Co., Ltd., a pioneer in mining and aggregate processing equipment, proudly presents the GF Series Vibrating Feeder—a robust, high-performance feeding system engineered to ensure precise and continuous material transfer in demanding industrial environments. Designed for durability, flexibility, and energy efficiency, the GF Series is ideal for feeding coarse or fine materials to crushers, screens, and conveyors in quarries, mines, recycling plants, and aggregate production lines. With its advanced vibration technology and intelligent control, the GF Series guarantees seamless workflow integration, reduced downtime, and enhanced productivity.

Product Overview

The GF Series Vibrating Feeder combines Liming’s decades of engineering expertise with cutting-edge vibration technology to deliver unmatched reliability in bulk material handling. Built to withstand heavy loads, abrasive materials, and harsh operating conditions, this feeder features a reinforced structure, wear-resistant components, and adjustable feeding rates. Whether used in primary crushing stations, secondary screening lines, or recycling facilities, the GF Series ensures consistent material flow, optimizing equipment performance and minimizing operational costs.

Key Features

- Heavy-Duty Construction

- Reinforced steel plate trough and sidewalls resist impact and abrasion from materials like granite, basalt, and recycled concrete.

- Replaceable wear liners (AR steel or polyurethane) extend service life and reduce maintenance costs.

- Advanced Vibration System

- High-efficiency vibration motors or exciter-driven mechanisms generate adjustable force for precise material control.

- Variable amplitude and frequency settings adapt to material characteristics (e.g., sticky, wet, or oversized).

- Energy-Saving Design

- Optimized vibration trajectory reduces power consumption by up to 25% compared to traditional feeders.

- Low-noise operation (<75 dB) complies with environmental and workplace safety regulations.

- Intelligent Automation

- PLC Control System: Enables real-time monitoring of feed rates, vibration intensity, and equipment status for automated adjustments.

- Overload protection and fault diagnostics prevent damage during blockages or irregular conditions.

- Easy Maintenance

- Modular design allows quick replacement of wear parts (liners, springs, motors) without disassembling the entire feeder.

- Centralized lubrication system ensures smooth operation and reduces manual upkeep.

Processing Capacity & Materials

- Throughput: 50–1,200 tons per hour (model-dependent).

- Max Feed Size: Up to 1,000 mm (adjustable based on crusher requirements).

- Material Types:

- Aggregates: Gravel, crushed stone, sand, limestone.

- Mining & Minerals: Iron ore, copper, gold, coal.

- Recycled Materials: Demolition waste, concrete, asphalt.

- Industrial Bulk: Slag, gypsum, fertilizers.

Applications

- Primary Crushing: Delivers raw materials evenly to jaw crushers or gyratory crushers.

- Quarry Operations: Ensures continuous feeding to crushing and screening lines.

- Recycling Facilities: Handles construction debris and concrete for reprocessing.

- Coal and Mineral Processing: Transfers bulk materials to conveyors, stockpiles, or processing units.

- Aggregate Production: Maintains steady feed to secondary/tertiary crushers and vibrating screens.