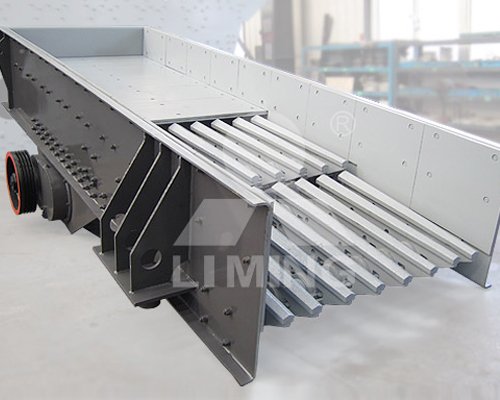

TSW Series Vibrating Feeder

Henan Liming Heavy Industry Science & Technology Co., Ltd., a global leader in mining and aggregate processing solutions, proudly presents the TSW Series Vibrating Feeder—a next-generation feeding system engineered to deliver unmatched precision, durability, and efficiency in heavy-duty material handling. Designed to seamlessly integrate with crushing and screening operations, the TSW Series ensures consistent, controlled feeding of bulk materials, maximizing productivity in quarries, mines, recycling plants, and aggregate production lines. With its innovative vibration technology, robust construction, and intelligent automation, the TSW Series is the ultimate choice for operators seeking reliability and cost-effectiveness.

Product Overview

The TSW Series Vibrating Feeder embodies Liming’s commitment to innovation and quality, combining advanced engineering with decades of industrial expertise. Built to handle abrasive, oversized, or heavy materials such as granite, iron ore, and recycled concrete, this feeder features a heavy-duty structure, wear-resistant components, and adaptive vibration control. Its modular design ensures easy integration into primary crushing stations, mobile plants, or complex processing lines, delivering smooth material flow and minimizing downtime.

Key Features

- Ultra-Durable Construction

- Reinforced steel plate trough and sidewalls with replaceable AR steel or polyurethane liners resist wear from abrasive materials.

- Heavy-duty shock absorbers and reinforced cross beams ensure stability under high-impact loads.

- Advanced Vibration Mechanism

- High-performance exciter with imported bearings (SKF/FAG) generates powerful, adjustable vibrations for precise material flow.

- Variable amplitude and frequency settings adapt to material properties (e.g., sticky, wet, or coarse).

- Energy-Saving Performance

- Optimized vibration trajectory reduces power consumption by up to 35% compared to traditional feeders.

- Low-noise operation (<75 dB) complies with environmental and workplace safety regulations.

- Smart Automation & Control

- PLC and IoT Integration: Real-time monitoring of feed rates, vibration intensity, and equipment health for seamless automation.

- Overload protection and fault diagnostics prevent damage during blockages or irregular conditions.

- Easy Maintenance

- Quick-release liners and modular components enable rapid replacement of wear parts without dismantling the entire feeder.

- Centralized lubrication system extends bearing life and reduces manual maintenance efforts.

Processing Capacity & Materials

- Primary Crushing Stations: Delivers large raw materials evenly to jaw crushers or gyratory crushers.

- Quarry & Mining Operations: Ensures continuous feeding to high-capacity crushing and screening lines.

- Recycling Facilities: Efficiently processes demolition debris and construction waste.

- Metallurgy & Coal Processing: Transfers bulk materials to stockpiles, conveyors, or processing units.

- Aggregate Production: Maintains steady feed to secondary/tertiary crushers and vibrating screens.

Applications

- Primary Crushing Stations: Delivers large raw materials evenly to jaw crushers or gyratory crushers.

- Quarry & Mining Operations: Ensures continuous feeding to high-capacity crushing and screening lines.

- Recycling Facilities: Efficiently processes demolition debris and construction waste.

- Metallurgy & Coal Processing: Transfers bulk materials to stockpiles, conveyors, or processing units.

- Aggregate Production: Maintains steady feed to secondary/tertiary crushers and vibrating screens.