Liming Jaw Crusher Diagram

September 28, 2025

Summary:This article provides an in-depth look at jaw crusher diagrams, focusing on Liming Heavy Industry's advanced crushing solutions. Learn about material processing workflows, equipment types, capacities, and innovative technologies that enhance efficiency in mining, construction, and recycling operations.

Introduction to Jaw Crusher and Key Materials

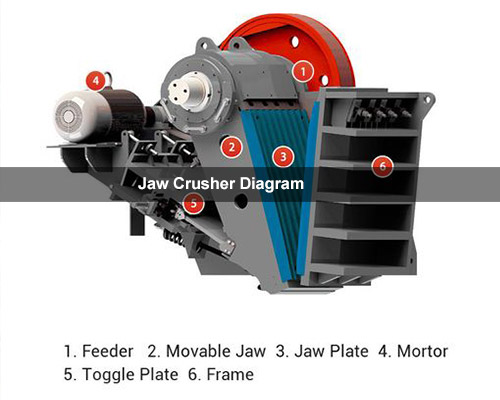

Jaw crusher is essential equipment in the mining and construction industries, designed to break down large, hard materials into smaller, manageable pieces. A jaw crusher diagram illustrates the mechanical structure and operational principles of these machines, highlighting components like the fixed and movable jaws, eccentric shaft, and toggle plate. At Liming Heavy Industry, our crusher handle a wide range of materials, including iron ore, copper ore, gold ore, manganese ore, river stone, granite, basalt, and other minerals with compressive strengths up to 320 MPa. These materials are critical in sectors such as mining, metallurgy, construction, highways, railways, and water conservancy.

Material Processing Workflow

The crushing process begins with raw material feeding into the crusher’s chamber, where the movable jaw compresses against the fixed jaw to fracture the material. A typical jaw crusher line diagram depicts stages from primary crushing (e.g., using Liming’s PE series like PE600X900) to secondary crushing (e.g., with PEW series like PEW250X1200). For instance, in a three-stage crushing setup, primary jaw crusher reduce large rocks to medium sizes, which are then processed by secondary crusher to achieve finer aggregates. Advanced control systems, such as automatic discharge adjustment and load monitoring, ensure optimal workflow efficiency and product consistency.

Application Range of Liming Jaw Crusher

Liming jaw crusher is versatile and widely applied across various industries. Our equipment, such as the European Type Jaw Crusher PEW860, is engineered for robust performance in:

- Mining Operations: Crushing ores like iron, copper, and gold for further processing.

- Construction Projects: Producing aggregates for roads, buildings, and infrastructure.

- Recycling Applications: Processing demolition waste and concrete for reuse.

- Quarrying: Handling limestone, granite, and basalt to produce standardized stone products.

The modular design of our crusher allows for integration into both stationary and mobile plants, catering to diverse operational needs.

Capacity and Types of Liming Jaw Crusher

Liming offers a comprehensive range of jaw crusher with varying capacities and specifications to match different production requirements. Below is a table summarizing key models:

| Series | Model | Feed Opening (mm) | Max Feed Size (mm) | Output Capacity (t/h) | Motor Power (kW) |

|---|---|---|---|---|---|

| PE Series | PE-150×250 | 150×250 | 125 | 5-20 | 15 |

| PE-400×600 | 400×600 | 350 | 15-60 | 30-37 | |

| PE-500×750 | 500×750 | 425 | 40-110 | 45-55 | |

| PE-600×900 | 600×900 | 480 | 90-180 | 55-75 | |

| PE-750×1060 | 750×1060 | 630 | 110-320 | 90-110 | |

| PE-900×1200 | 900×1200 | 750 | 220-450 | 110-132 | |

| PE-1000×1200 | 1000×1200 | 850 | 280-560 | 110-160 | |

| PE-1200×1500 | 1200×1500 | 1020 | 400-800 | 160-220 | |

| PE-1500×1800 | 1500×1800 | 1200 | 520-1100 | 280 | |

| PEW Series | PEW860 | 860×1100 | 930 | 150-300 | 132 |

| PEW250×1200 | 250×1200 | 210 | 20-60 | 37-45 | |

| C6X Series | C6X110 | 1100×850 | – | 150-1500* | 160 |

| C6X125 | 1250×950 | – | 150-1500* | 160 | |

| C6X145 | 1450×1100 | – | 150-1500* | 200 | |

| C6X160 | 1600×1200 | – | 150-1500* | 250 | |

| C6X200 | 2000×1500 | – | 150-1500* | 400 | |

| HJ Series | HJ110 | 2530×2875 | – | 215-510 | 110-150 |

These crusher is available in primary (PE series) and secondary (PEW series) configurations, ensuring flexibility for high-volume operations. The liming jaw crusher diagram often highlights features like large feed openings and high reduction ratios, which contribute to their superior capacity.

Technological Innovations in Liming Jaw Crusher

Liming integrates cutting-edge technologies to enhance crusher performance and reliability. Key innovations include:

- Finite Element Analysis (FEA): Used to optimize the crusher’s structure for increased durability and reduced weight.

- Centralized Lubrication Systems: Automatically lubricate bearings to minimize maintenance downtime.

- Hydraulic Adjustment Mechanisms: Allow quick and precise control of the discharge opening for consistent product sizing.

- Wear-Resistant Materials: High manganese steel jaw plates (e.g., Mn18Cr2) extend service life in abrasive conditions.

- Automated Control Systems: Monitor parameters like load and output size to maintain optimal crushing conditions and prevent overloads.

These advancements are evident in the jaw crusher line diagram, which showcases the intelligent design of components like the eccentric shaft and toggle system.

Common Challenges and Solutions

Operators often face issues such as uneven wear, blockages, and efficiency fluctuations. Liming addresses these with practical solutions:

- Challenge: Material Blockages – Can halt production and damage equipment. Solution: Our crusher feature hydraulic clearing systems to safely dislodge trapped material.

- Challenge: Irregular Product Size – Affects downstream processes. Solution: Adjustable discharge settings and precision-engineered chambers ensure uniform output.

- Challenge: High Maintenance Costs – Due to frequent part replacements. Solution: Durable components and easy-access designs reduce servicing time and costs.

By referring to a jaw crusher diagram, operators can better understand component interactions and implement these solutions effectively.

Case Study: 100TPH Feldspar Crushing Line in Indonesia

Location: Jambi, Indonesia

Project Scope: A 100-ton-per-hour feldspar processing line for ceramic and floor tile production.

Equipment Used:

- Primary Crusher: Liming PE600X900 Jaw Crusher

- Secondary Crusher: 4 units of PEW250X1200 Jaw Crusher

- Tertiary Crusher: 2 units of HPT220 Cone Crusher and 2 units of HPT300 Cone Crusher

- Supporting Equipment: GZD vibrating feeders, 2YZS1860 vibrating screens, and 2PG0608 roller crusher

Results: Since commissioning in March 2015, the line has operated with minimal downtime, achieving a consistent product size of 0-5 mm and meeting the client’s quality requirements. The optimized jaw crusher line diagram for this project ensured balanced load distribution across crushing stages, maximizing efficiency.

Why Choose Liming Jaw Crusher?

Liming Heavy Industry stands out for its commitment to quality and innovation. Reasons to choose our products include:

- Proven Reliability: Crusher like the PEW860 are built with heavy-duty components for long-term operation.

- Global Support: Comprehensive after-sales services, including technical consultation and spare parts supply.

- Customization Options: Tailored solutions for specific material types and output requirements.

- Energy Efficiency: Designs that reduce power consumption while maintaining high throughput.

Our liming jaw crusher diagram reflects these advantages, emphasizing user-friendly maintenance and robust construction.

Conclusion

Understanding jaw crusher diagrams is crucial for optimizing crushing operations. Liming Heavy Industry’s range of jaw crusher, from the PE series to the advanced PEW models, offers reliable solutions for diverse applications. With features like automated controls, high capacities, and innovative designs, our equipment ensures efficient material processing and reduced operational costs. For more details on our products, including detailed diagrams and specifications, contact Liming Heavy Industry today.