How Do Rock Crushers and Crushing Operations Work?

September 30, 2025

Summary:This comprehensive article explains how rock crushers work in crushing operations, specifically highlighting Liming Heavy Industry's equipment and expertise. The content covers basic rock crusher working principles, different types of crushers (jaw, impact, cone,VSI, and mobile crushers), stages of crushing operations, and key operational considerations.

In mining, construction, and quarry operations, understanding the rock crusher working principles is essential for optimizing production and reducing operational costs. Rock crushing is the first step in converting large blasted rock materials or natural stones into usable aggregates. As a leading manufacturer of mineral processing equipment, Liming Heavy Industry provides comprehensive solutions that cover the entire rock crusher working process from primary crushing to fine grinding.

The Basic Principles of Rock Crusher Working

At its core, rock crusher working involves reducing large rocks into smaller stones, gravel, or rock dust through mechanical forces. The fundamental concept behind all crushing operations is applying sufficient force to materials to break them along their natural fracture lines. Different crusher employ various crushing mechanisms including compression, impact, and attrition, depending on the application requirements and material characteristics.

In typical rock crusher working processes, raw materials (of various sizes) are usually fed into the primary crusher’s hopper by dump trucks, excavators, or wheeled front loaders. Feeding devices such as conveyors or vibrating grates control the rate at which material enters the crusher, often with preliminary screening devices that allow smaller-sized to automatically bypass the crusher to improve efficiency. The primary crusher reduces large pieces to a size that can be processed by downstream machinery.

Types of Rock Crusher and Their Working Mechanisms

Different crushing applications require specific types of equipment. Liming Heavy Industry offers a complete range of crusher designed for various stages of the rock crusher working process, each with unique operating principles and optimal applications.

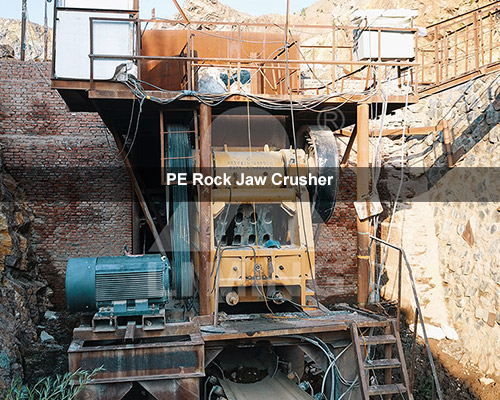

Jaw Crusher

Jaw crusher is primary crusher that use two vertical jaws to create a V-shaped chamber where rocks are crushed. The fixed jaw remains stationary while the movable jaw exerts force on the rocks through an elliptical motion. This compression-style rock crusher working mechanism is ideal for hard and abrasive materials.

Our PE and PEX series jaw crusher, including models like PE-400×600, PE-500×750, and PEX-250×1000, feature optimized crushing chambers and robust construction for high efficiency in primary crushing applications. These crusher typically handle feed sizes up to 750mm and produce uniform end products with minimal fines generation.

Impact Crusher

Impact crusher utilize impact force rather than pressure to crush materials. In these machines, rocks are fed into a rotating rotor equipped with blow bars that throw the materials against stationary impact plates. This rock crusher working method is particularly effective for medium-hard to hard materials with low silica content.

Liming’s PF series impact crusher, including models like PF-1010, PF-1214, and PF-1315, feature a unique design that combines high reduction ratios with excellent product shape. The hydraulic adjustment system allows quick configuration changes, while the durable blow bars made of high-chromium iron ensure long service life even under demanding conditions.

Vertical Shaft Impact (VSI) Crusher

VSI crusher, also known as sand making machines, utilize a high-speed rotor that throws rocks against a stationary anvil ring or rock shelf. This “rock-on-rock” or “rock-on-iron” rock crusher working principle produces well-shaped cubical products ideal for concrete and asphalt production.

Our VSI series, including VSI-3000, VSI-5000, and VSI-8000 models, can achieve rotor speeds of up to 99m/s, effectively breaking down even small feed materials. These crusher is perfect for producing manufactured sand and shaping aggregates, with the unique rock-bed crushing action significantly reducing wear costs compared to conventional impact crusher.

Mobile Crushing Plants

Mobile crusher integrate crushing, screening, and conveying equipment on a single chassis, providing unparalleled flexibility for various job sites. Unlike stationary plants, the rock crusher working process in mobile units can be quickly relocated between sites, significantly reducing transportation costs of raw materials.

Our K series mobile crushing plants, including models like NK9526-2, NK9532-2, and NK8518-2, offer flexible configuration options with jaw, impact, or cone crusher as the main crushing unit. These plants can be powered either by an external power source or by an integrated diesel generator, making them suitable for remote locations without reliable grid power.

Stages of Rock Crushing Operations

Understanding the complete rock crusher working process requires knowledge of how different crushing stages work together in a production circuit. Most aggregate and mining operations utilize multiple crushing stages to achieve the desired product specifications efficiently.

Primary Crushing

Primary crushing represents the first stage in the rock crusher working circuit, where large rocks (typically up to 1.5 meters in diameter) are reduced to 150-250mm. Jaw crusher and gyratory crusher is commonly used at this stage due to their high capacity and ability to handle large feed sizes. Our PE-750×1060 and PE-900×1200 jaw crusher is popular choices for primary crushing applications, offering capacities ranging from 72 to 240 tons per hour depending on material characteristics and discharge setting.

Secondary Crushing

Secondary crushing further reduces the material size to 20-70mm, preparing it for the final crushing stage. Cone crusher and impact crusher is typically employed at this stage of rock crusher working. These crusher produce a more uniform product size distribution and better particle shape compared to primary crusher. Our PF-1214 and PF-1315 impact crusher excel in secondary crushing applications, particularly when processing limestone and other medium-hard materials.

Tertiary and Quaternary Crushing

For applications requiring precise product control or ultra-fine materials, tertiary and quaternary crushing stages are incorporated into the rock crusher working circuit. Vertical shaft impactors and cone crusher with finer cavity profiles are typically used at these stages. Our VSI series crusher produce excellent cubical products ideal for concrete and asphalt production, with the added benefit of being able to control the product gradation through rotor speed adjustment.

Key Considerations in Rock Crusher Working Processes

Optimizing rock crusher working efficiency requires attention to several operational factors that directly impact productivity, product quality, and operational costs.

Material Characteristics

The hardness, abrasiveness, moisture content, and feed size distribution of the raw material significantly influence crusher selection and rock crusher working parameters. Hard and abrasive materials like granite and basalt require jaw and cone crusher that utilize compressive force, while softer materials like limestone can be efficiently processed with impact crusher.

Feed Control

Proper feeding is critical to efficient rock crusher working. An uneven feed distribution or overfeeding can lead to poor product quality, reduced throughput, and accelerated wear. Modern crushing plants incorporate advanced control systems that monitor crusher load and adjust the feed rate accordingly to maintain optimal rock crusher working conditions.

Product Gradation Requirements

The desired end product specifications determine the appropriate crushing circuit configuration and rock crusher working parameters. Operations requiring multiple products may need additional screening stages and closed-circuit crushing systems where oversized material is recirculated back to the crusher for further reduction.

Liming Heavy Industry Crusher Specifications

Our comprehensive range of crushing equipment is designed to meet diverse production requirements across various applications. The following table presents key specifications for some of our popular crusher models:

| Model | Type | Max Feed Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| PE-400×600 | Jaw Crusher | 340 | 10-35 | 30 |

| PE-600×900 | Jaw Crusher | 500 | 30-85 | 55-75 |

| PF-1010 | Impact Crusher | 350 | 50-80 | 55-75 |

| PF-1214 | Impact Crusher | 350 | 130-180 | 132-160 |

| VI-5000 | VSI Crusher | 65 | 80-150 | 150-220 |

| VI-8000 | VSI Crusher | 70 | 250-380 | 320-440 |

Conclusion

Understanding the intricacies of rock crusher working principles is essential for optimizing crushing operations in mining, quarrying, and construction applications. From primary jaw crushing to fine shaping with vertical shaft impactors, each stage in the crushing circuit plays a vital role in determining the final product quality and operational efficiency.

At Liming Heavy Industry, we combine decades of engineering expertise with innovative technologies to deliver robust crushing solutions tailored to specific customer requirements. Our comprehensive product range, from stationary crusher to mobile crushing plants, ensures that customers can find the ideal equipment configuration for their unique operational needs.

By selecting the appropriate crusher types and optimizing the rock crusher working parameters, operations can achieve higher throughput, better product quality, and reduced operating costs. With proper maintenance and operational practices, modern crushing equipment can deliver years of reliable service in even the most demanding applications.