Price of Portable Crusher Producing Asphalt Aggregates for Maverick Materials

October 13, 2025

Summary:The price of a portable crusher for producing asphalt aggregates varies based on capacity, features, and brand, but it is a worthwhile investment for companies like Maverick Materials.

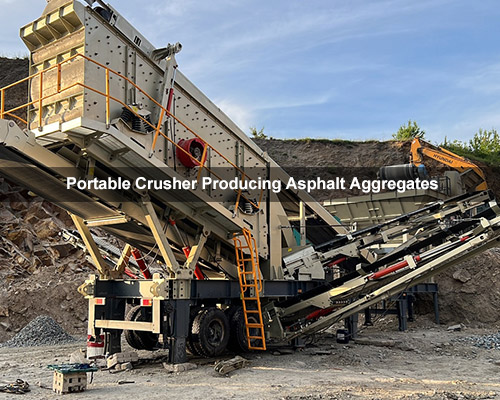

In the construction and materials industry, Maverick Materials relies on efficient equipment like portable crushers to produce high-quality asphalt aggregates. These machines are essential for recycling asphalt and creating durable aggregates for roads and infrastructure projects. Understanding the price of a portable crusher is crucial for budgeting and optimizing operations. This article delves into the costs, benefits, and key considerations for Maverick Materials when investing in portable crushers for asphalt aggregate production.

What is a Portable Crusher?

A portable crusher is a mobile crushing machine that can be easily transported to different job sites. It is designed to process materials like rock, concrete, and asphalt into smaller, reusable aggregates. For companies like Maverick Materials, portable crushers offer flexibility and efficiency in producing asphalt aggregates on-site, reducing transportation costs and environmental impact.

Benefits of Using Portable Crushers for Asphalt Aggregates

Portable crushers provide numerous advantages for Maverick Materials, including cost savings, increased productivity, and sustainability. By crushing asphalt on-site, companies can reuse old pavement, minimize waste, and lower material costs. Additionally, portable crushers enable quick setup and teardown, making them ideal for temporary projects or remote locations.

Factors Affecting the Price of Portable Crushers

The price of a portable crusher for producing asphalt aggregates can range from $50,000 to $500,000 or more, depending on several factors. Key considerations include:

- Capacity and Size: Higher-capacity models with advanced features cost more.

- Brand and Quality: Reputable brands may command premium prices but offer better durability.

- Additional Features: Options like diesel-electric power, automation, and dust control systems can increase costs.

- Maintenance and Operating Costs: Factor in long-term expenses for parts, fuel, and labor.

For Maverick Materials, investing in a mid-range portable crusher (around $100,000 to $300,000) often balances performance and affordability, especially for medium to large-scale projects.

Case Study: Maverick Materials’ Use of Portable Crushers

Maverick Materials has successfully integrated portable crushers into their operations to produce asphalt aggregates for road construction. By using a $200,000 portable crushing plant, they reduced material costs by 30% and improved project timelines. This investment allowed them to recycle existing asphalt, align with sustainability goals, and enhance profitability.

How to Choose the Right Portable Crusher for Your Needs

When selecting a portable crusher for asphalt aggregates, Maverick Materials should assess project scale, budget, and specific requirements. Consider consulting with industry experts, comparing multiple quotes, and evaluating the machine’s efficiency and environmental compliance. Renting or leasing options can also be cost-effective for short-term needs.

Conclusion

The price of a portable crusher for producing asphalt aggregates varies based on capacity, features, and brand, but it is a worthwhile investment for companies like Maverick Materials. By understanding the factors that influence costs and leveraging the benefits of on-site crushing, businesses can achieve significant savings and operational efficiency. For tailored advice, reach out to equipment suppliers to get accurate pricing and support for your aggregate production needs.