Principle Diagram for Jaw Crusher

October 10, 2025

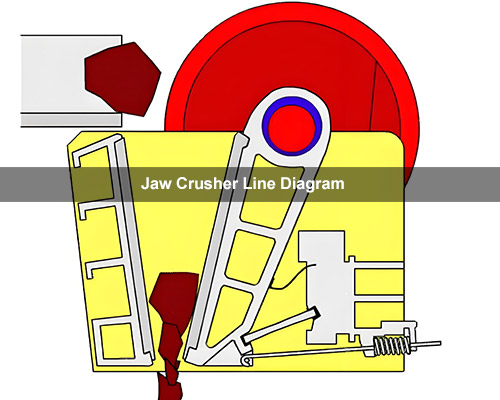

Summary:This article provides an in-depth explanation of the principle diagram for jaw crusher, focusing on how it demonstrates the working mechanism of primary jaw crushers. As a trusted manufacturer, Liming Heavy Industry offers a range of jaw crushers designed for efficient crushing in mining and stone processing applications. By exploring the primary jaw crusher diagram, customers can better understand equipment operation and make informed decisions for their projects.

Introduction to Jaw crusher and Their Importance

Jaw crusher is essential equipment in the mining and construction industries, used for primary crushing of hard materials like rocks and ores. At Liming Heavy Industry, we specialize in manufacturing robust jaw crushers that ensure high efficiency and durability. Understanding the principle diagram for jaw crusher is crucial for operators and engineers to optimize performance and troubleshoot issues effectively. This diagram visually represents the key components and their interactions during the crushing process.

Key Components in a Primary Jaw Crusher Diagram

A typical primary jaw crusher diagram includes several critical parts: the fixed jaw, movable jaw, eccentric shaft, toggle plate, and crushing chamber. The principle diagram for jaw crusher shows how these elements work together to reduce large stones into smaller particles. For instance, the eccentric shaft drives the movable jaw in a reciprocating motion, while the toggle plate provides safety against overloads. At Liming Heavy Industry, our jaw crushers, such as those in our standard series, incorporate these components with precision engineering to deliver reliable performance in various applications, including stone crushing and mineral processing.

How the Principle Diagram for Jaw Crusher Illustrates Working Mechanism

The principle diagram for jaw crusher effectively demonstrates the crushing process through a series of mechanical actions. When material enters the crushing chamber, the movable jaw compresses it against the fixed jaw, breaking it down through repeated cycles. This diagram highlights the role of the eccentric shaft in generating the necessary force, making it easier for customers to visualize operation and maintenance steps. By referring to a primary jaw crusher diagram, users can identify potential wear points and implement preventive measures, ensuring longer equipment life. Liming Heavy Industry’s jaw crusher is designed with user-friendly features, backed by detailed diagrams in our product documentation.

Applications and Benefits of Understanding Jaw Crusher Diagrams

Grasping the principle diagram for jaw crusher enables customers to select the right equipment for their specific needs, such as primary crushing in quarry operations or mineral processing plants. A well-interpreted primary jaw crusher diagram can aid in training operators, reducing downtime, and enhancing safety. At Liming Heavy Industry, we provide comprehensive support, including technical guides that feature these diagrams, to help clients maximize the efficiency of our products. Our jaw crusher is integral to systems like screening and mineral separation, ensuring seamless integration in full production lines.

Conclusion

In summary, the principle diagram for jaw crusher is a vital tool for understanding the inner workings of primary crushing equipment. By studying the primary jaw crusher diagram, customers can improve operational efficiency and make informed choices. Liming Heavy Industry remains committed to delivering high-quality jaw crushers and related equipment, supported by expert knowledge and resources. For more information on our products, feel free to reach out to our team.