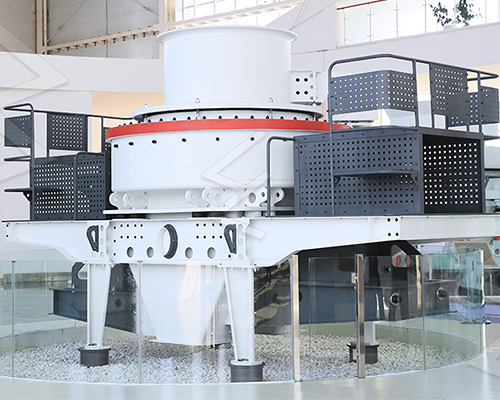

VSI5X Vertical Shaft Impact Crusher

Henan Liming Heavy Industry Science & Technology Co., Ltd., a leading innovator in mining and aggregate processing equipment, introduces the VSI5X Vertical Shaft Impact Crusher—an advanced crushing machine designed to deliver superior performance in sand production and fine aggregate shaping. Combining robust engineering with intelligent automation, the VSI5X Crusher excels in processing hard and abrasive materials, producing high-quality sand and uniformly shaped aggregates for construction, infrastructure, and industrial applications. With its optimized design and low operational costs, this crusher embodies Liming’s commitment to innovation, durability, and customer-centric solutions.

Product Overview

The VSI5X Vertical Shaft Impact Crusher utilizes a high-speed rotor and rock-on-rock or rock-on-iron crushing principles to achieve precise particle shaping and gradation control. Ideal for processing materials like granite, basalt, and quartz, it is widely used in artificial sand making, aggregate production, and mineral processing. Featuring a heavy-duty structure, hydraulic adjustment system, and wear-resistant components, the VSI5X ensures reliable operation in demanding environments while maintaining low energy consumption. Its versatility makes it suitable for both stationary plants and mobile crushing systems.

Key Features

- Optimized Rotor Design

- Deep-cavity, four-port rotor enhances material throughput by 20% and extends service life.

- Unique flow channel design minimizes wear and improves crushing efficiency.

- Hydraulic Lid Opening System

- Enables quick and safe access to the crushing chamber for maintenance and inspection.

- Adjustable discharge opening allows real-time control over product size and gradation.

- Durable Wear-Resistant Components

- High-chrome alloy impact blocks and tungsten carbide-tipped rotor tips resist extreme abrasion.

- Modular design simplifies replacement of wear parts, reducing downtime.

- Intelligent Control System

- PLC-based automation (optional) provides real-time monitoring of operational parameters.

- Overload protection and vibration sensors prevent equipment damage.

- Energy Efficiency & Eco-Friendliness

- Optimized rotor speed and energy-saving motor reduce power consumption by up to 25%.

- Closed-loop dust suppression system minimizes environmental impact.

Processing Capacity & Materials

- Throughput: 50–650 tons per hour (model-dependent).

- Max Feed Size: Up to 60 mm.

- Adjustable Output Size: 0–5 mm, 5–10 mm, or customized gradations.

- Materials Processed: Granite, basalt, limestone, quartz, iron ore, cement clinker, and construction waste.

Applications

- Artificial Sand Manufacturing: Produces high-quality sand for concrete, asphalt, and dry-mix mortar.

- Aggregate Production: Shapes cubical aggregates for highways, railways, and architectural projects.

- Mining & Quarrying: Fine crushing of ores and minerals for beneficiation processes.

- Recycling: Converts construction waste and concrete debris into reusable materials.

- Industrial Materials: Processes glass, slag, and refractory materials for specialized industries.