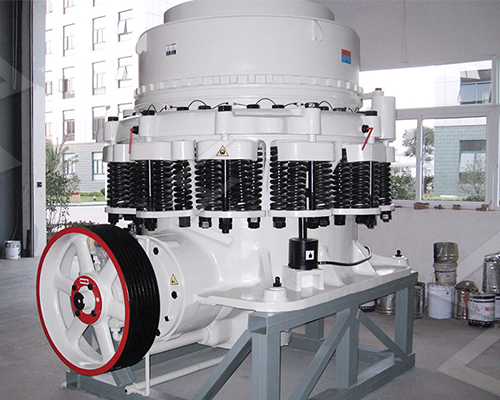

CS Spring Cone Crusher

Henan Liming Heavy Industry Science & Technology Co., Ltd., a pioneer in mining and aggregate processing equipment, introduces the CS Spring Cone Crusher—a time-tested, high-performance crushing solution designed for secondary and tertiary crushing of medium-to-high hardness materials. Renowned for its reliability, simplicity, and cost-effectiveness, the CS Spring Cone Crusher is a cornerstone of efficient mineral processing, quarrying, and construction applications. With decades of engineering expertise, Liming’s CS series continues to deliver consistent output, making it a trusted choice for global operators.

Product Overview

The CS Spring Cone Crusher combines a robust mechanical design with advanced crushing principles to achieve high productivity and precise particle size control. Utilizing a spring-based overload protection system, this crusher automatically adjusts to varying material hardness and feed conditions, ensuring stable operation and minimal downtime. Ideal for processing granite, basalt, iron ore, and other abrasive materials, the CS Crusher is engineered for durability and ease of maintenance, making it a versatile solution for both stationary and mobile plants.

Key Features

- Spring Safety System

- Integrated spring release mechanism protects the crusher from overload damage.

- Automatic reset ensures continuous operation without manual intervention.

- High Crushing Efficiency

- Optimized cavity design and steep crushing angle enhance material reduction and throughput.

- Uniform particle size distribution with minimal fines generation.

- Durable Construction

- Heavy-duty alloy steel frame and high manganese steel mantles/concaves withstand abrasive wear.

- Reinforced main shaft and bearings ensure long-term reliability.

- Easy Maintenance

- Modular design simplifies replacement of wear parts (mantle, concave, springs).

- Hydraulic adjustment system for quick discharge setting changes.

- Cost-Effective Operation

- Energy-efficient motor reduces power consumption.

- Low operational costs due to minimal maintenance requirements.

Processing Capacity & Materials

- Throughput: 20–1,350 tons per hour (model-dependent).

- Max Feed Size: Up to 300 mm.

- Adjustable Output Size: 3–64 mm (fine to coarse).

- Materials Processed: Granite, basalt, quartzite, iron ore, limestone, copper ore, and concrete.

Applications

- Mining: Secondary crushing of ores for mineral extraction and smelting.

- Aggregate Production: Manufacturing high-quality sand and gravel for construction and infrastructure.

- Quarrying: Processing hard rock into roadbase, railway ballast, or architectural stone.

- Cement Industry: Crushing raw materials and clinker for cement production.

- Recycling: Repurposing concrete and demolition waste into reusable aggregates.