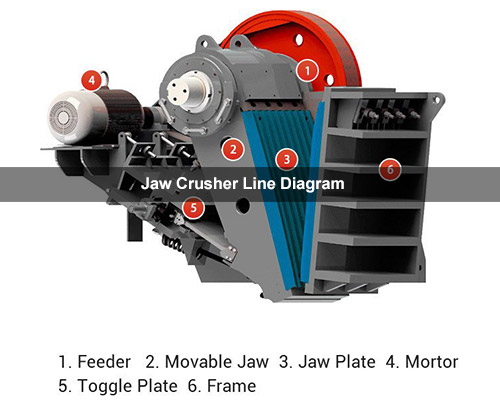

Jaw Crusher Line Diagram

October 10, 2025

Summary:This article provides an in-depth look at the jaw crusher line diagram, covering material types, crushing processes, applications, and innovative solutions from Liming Heavy Industry for efficient and reliable operations.

In the mining and construction industries, jaw crushers play a critical role in reducing large rocks and ores into smaller, manageable sizes. A jaw crusher line diagram visually represents the components and flow of the crushing process, helping operators optimize performance and troubleshoot issues. At Liming Heavy Industry, we specialize in manufacturing high-quality jaw crushers, such as the PE and PEX series, designed to handle various materials with precision and reliability. This article delves into the key aspects of jaw crushers, from material types to innovative technologies, and highlights why our equipment stands out in the global market.

Material Introduction

Jaw crushers are used to process a wide range of materials, including hard rocks like granite, basalt, and iron ore, as well as softer aggregates such as limestone and sandstone. Understanding the properties of these materials—such as hardness, abrasiveness, and moisture content—is essential for selecting the right crusher. For instance, our jaw crushers are engineered to handle high-abrasion materials efficiently, ensuring long-term durability and reduced maintenance costs.

Material Crushing Process Flow

The crushing process begins with the feeding of raw material into the jaw crusher, where it is compressed between a fixed and a movable jaw plate. The jaw crusher line diagram illustrates this sequence, showing how the material is gradually reduced in size through multiple stages. Key steps include primary crushing (handled by jaw crushers like our PE series), secondary crushing, and screening. This streamlined process minimizes energy consumption and maximizes output, making it ideal for applications in quarrying, mining, and recycling.

Application Range of Our Crusher Equipment

Liming Heavy Industry’s jaw crushers, including models like PE500×750, PE600×900, and PEX250×1000, are widely used in diverse sectors. They are employed in mining operations for ore processing, in construction for aggregate production, and in industrial settings for recycling concrete and demolition waste. Our equipment is designed to adapt to various environments, from stationary plants to mobile setups, providing versatile solutions for clients worldwide.

Jaw Crusher Capacity and Types

Our jaw crushers come in different types and capacities to suit specific needs. The PE series, for example, offers capacities ranging from 15 to 800 tons per hour, depending on the model (e.g., PE400×600 handles up to 60 t/h, while PE1200×1500 can process over 800 t/h). The PEX series is ideal for fine crushing, with capacities tailored for secondary applications. Understanding the jaw crusher line diagram helps in selecting the right type—whether for high-capacity primary crushing or precision secondary crushing—ensuring optimal performance and cost-efficiency.

Technology and Innovation in Jaw Crusher Equipment

At Liming Heavy Industry, we integrate advanced technologies into our jaw crushers to enhance efficiency and sustainability. Innovations include hydraulic adjustment systems for easy setting changes, wear-resistant materials like manganese steel for longer component life, and energy-saving designs that reduce operational costs. For example, our jaw crushers feature optimized crushing chambers that improve particle shape and throughput, aligning with the principles shown in a typical jaw crusher line diagram. These innovations ensure our equipment meets the evolving demands of the industry.

Common Challenges and Solutions

Operators often face challenges such as jaw plate wear, uneven material feeding, and downtime due to blockages. Based on the jaw crusher line diagram, we recommend regular maintenance, including jaw plate inspection and lubrication, to prevent wear. For feeding issues, our crushers come with vibrating feeders and adjustable settings to ensure consistent material flow. In case of blockages, our designs include safety mechanisms that minimize risks and allow for quick clearing. These solutions, backed by our technical support, help clients maintain high productivity.

Case Study: Real-World Application with Data

In a recent project in a granite quarry in Asia, our PE600×900 jaw crusher was deployed for primary crushing. The operation processed over 200 tons of granite per hour, with a final product size of 150 mm. Key results included a 25% reduction in energy consumption compared to previous equipment and a 95% availability rate over six months. This case demonstrates how our jaw crushers, guided by an efficient jaw crusher line diagram, deliver tangible benefits in terms of capacity, reliability, and cost savings.

Why Choose Liming Heavy Industry?

Choosing Liming Heavy Industry means investing in reliability, innovation, and global expertise. Our jaw crushers are certified to international standards and come with comprehensive after-sales services, including installation support and spare parts availability. With over decades of experience, we have built a reputation for delivering customized solutions that address specific client needs. The jaw crusher line diagram is just one tool we use to educate and empower our customers, ensuring they achieve their production goals efficiently.

Conclusion

The jaw crusher line diagram serves as a vital reference for optimizing crushing operations, from material handling to final output. At Liming Heavy Industry, our range of jaw crushers, including the PE and PEX series, combines robust design with cutting-edge technology to meet diverse industrial requirements. By addressing common challenges and providing data-driven solutions, we help clients enhance their productivity and profitability. For more information on our products, contact us to discover how we can support your projects with reliable and efficient crushing equipment.