Copper Ore Crusher

Introduction to Copper Ore

Copper remains one of the most crucial industrial metals, essential for electrical wiring, renewable energy systems, and electronics. With global copper demand projected to grow 3.5% annually through 2030, efficient ore processing has never been more critical. Proper crushing using advanced equipment like Liming Heavy Industry’s crushers forms the foundation of profitable copper extraction.

Copper Ore Mining Process Overview

1. Exploration and Site Development

Modern copper mining begins with extensive geological surveys using advanced technologies like 3D seismic imaging to identify viable deposits.

2. Extraction Methods

Primary copper extraction techniques include:

- Open-pit mining (for deposits within 300m of surface)

- Underground mining (for deeper vein deposits)

- In-situ leaching (for specific ore types)

3. Ore Transportation

Run-of-mine (ROM) copper ore is transported to primary crushing stations, typically located near the mine pit.

Copper Ore Processing Flow

1. Primary Crushing Stage

The Liming C6X Jaw Crusher excels in primary copper ore reduction, handling large feed sizes up to 1250mm with throughput capacities from 160-1500TPH.

2. Secondary Crushing

The Liming HST Single Cylinder Hydraulic Cone Crusher provides precise intermediate crushing, producing uniform 50-150mm particles ideal for grinding circuits.

3. Tertiary Crushing

For final size reduction, the Liming HPT Multi-cylinder Hydraulic Cone Crusher delivers consistent 10-30mm output with exceptional energy efficiency.

4. Grinding and Flotation

Crushed ore undergoes further processing through ball mills and flotation cells to concentrate copper minerals.

Essential Copper Ore Crushing Equipment

1. Primary Crushers – Liming C6X Series Jaw Crushers

Key features for copper processing:

- Optimized crushing cavity increases capacity by 15-30%

- Integrated motor base reduces installation space

- Durable manganese steel components withstand abrasive copper ores

- Models available from 160-1500TPH capacity

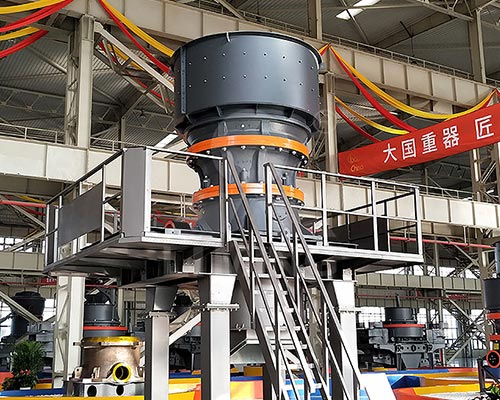

2. Secondary Crushers – HST/HPT Cone Crusher Series

Advanced cone crusher technology offers:

- Fully hydraulic adjustment for quick setting changes

- Intelligent automated control systems

- Dual-acting hydraulic cylinders for better protection

- Special bronze bearings for heavy-duty operation

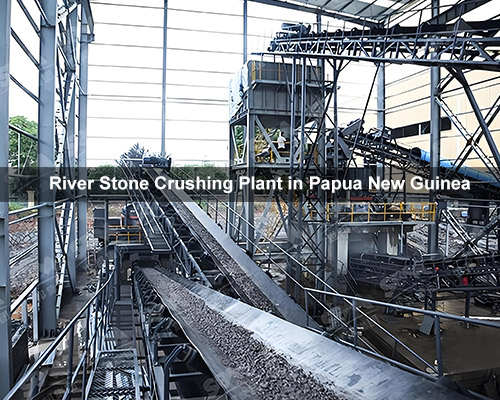

3. Mobile Crushing Solutions – Liming Track-Mounted Plants

For flexible copper processing:

- Liming MJ Series Mobile Jaw Crusher Plants

- Liming MP Series Mobile Impact Crusher Plants

- Integrated screening and conveying systems

Copper Market Outlook 2023-2030

Key industry drivers:

- Global transition to renewable energy systems (solar/wind require 5x more copper than fossil fuel plants)

- Electric vehicle adoption (EVs use 3-4x more copper than conventional vehicles)

- Infrastructure development in emerging economies

- Declining ore grades increasing demand for efficient processing equipment

Why Choose Liming Heavy Industry for Copper Processing?

1. Ore-Specific Engineering

We customize crusher configurations based on your specific copper ore characteristics (oxide vs sulfide, hardness, abrasiveness).

2. Energy Efficient Designs

Our HPT series cone crushers reduce energy consumption by up to 40% compared to conventional crushers.

3. Comprehensive Support

Global service network provides:

- On-site installation supervision

- Operator training programs

- Predictive maintenance services

Maintenance Best Practices for Copper Ore Crushers

1. Wear Part Management

Recommended replacement intervals for Liming crushers processing copper ore:

- Jaw plates: 400-600 operating hours

- Concave/mantle: 800-1200 hours

- Impact hammers: 300-500 hours

2. Lubrication Systems

Our automatic lubrication systems ensure proper bearing protection in dusty copper processing environments.

3. Vibration Monitoring

Integrated sensors detect abnormal operation before costly damage occurs.

Future Trends in Copper Ore Processing

1. Automation and Smart Crushing

Liming’s intelligent control systems automatically adjust crusher settings based on ore characteristics.

2. Waterless Processing

New dry crushing technologies reduce water usage in arid mining regions.

3. Hybrid Power Systems

Mobile crushing plants with diesel-electric hybrid drives cut fuel costs by 25-35%.

Conclusion

Selecting the right crushing equipment significantly impacts copper processing efficiency and profitability. Liming Heavy Industry’s C6X Jaw Crushers, HST/HPT Cone Crushers, and mobile crushing plants offer robust, energy-efficient solutions for all copper ore processing requirements. With over 30 years of mineral processing experience, we can help optimize your copper crushing circuit for maximum productivity.