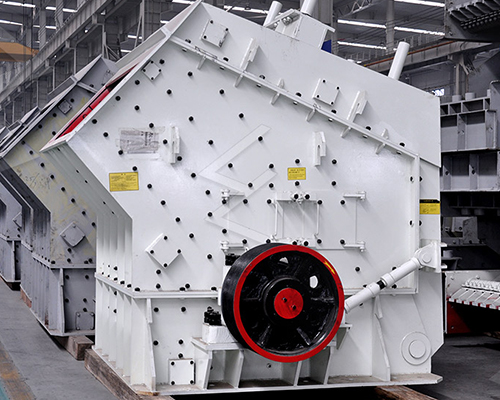

PF Series Impact Crusher

Henan Liming Heavy Industry Science & Technology Co., Ltd., a leader in mining and aggregate processing equipment, presents the PF Series Impact Crusher—a robust and versatile solution designed for primary and secondary crushing of medium-hard materials. Renowned for its simple structure, high efficiency, and low maintenance costs, the PF Series has become a cornerstone in quarries, recycling operations, and construction projects worldwide. With decades of engineering refinement, Liming’s PF crushers deliver consistent performance, exceptional durability, and superior particle shape, making them ideal for operators seeking reliable and economical crushing solutions.

Product Overview

The PF Series Impact Crusher utilizes impact force to crush materials, featuring a heavy-duty rotor, high-chrome blow bars, and a hydraulic adjustment system. Engineered for processing limestone, concrete, granite, and other abrasive materials, this crusher excels in producing well-shaped aggregates with minimal fines. Its straightforward design ensures ease of operation and maintenance, while its adaptability makes it suitable for both stationary plants and mobile crushing systems.

Key Features

- High Crushing Efficiency

- Optimized rotor design and impact plates ensure powerful impact force and high reduction ratios.

- Cubic-shaped output ideal for construction aggregates and industrial minerals.

- Durable Wear Parts

- High-chrome alloy blow bars and impact plates resist wear in demanding conditions.

- Modular design allows quick replacement of wear components without disassembling the rotor.

- Hydraulic Adjustment System

- Easily adjust the discharge gap to control output size and maintain optimal productivity.

- Overload protection mechanism safeguards the crusher from damage caused by uncrushable materials.

- Energy-Saving Design

- Efficient motor and optimized crushing chamber reduce power consumption by 15–20%.

- Low operational costs due to minimal downtime and extended component lifespan.

- User-Friendly Maintenance

- Openable rear frame provides easy access to internal components for inspection and servicing.

- Simplified lubrication system ensures smooth operation and reduces maintenance frequency.

Processing Capacity & Materials

- Throughput: 50–800 tons per hour (model-dependent).

- Max Feed Size: Up to 500 mm.

- Adjustable Output Size: 10–60 mm (customizable based on requirements).

- Materials Processed: Limestone, dolomite, granite, basalt, concrete, construction waste, coal, and gypsum.

Applications

- Quarrying & Mining: Primary and secondary crushing of aggregates and ores.

- Construction: Producing base materials for roads, railways, and concrete production.

- Recycling: Processing demolition debris and concrete into reusable aggregates.

- Cement Industry: Crushing raw materials and clinker for cement manufacturing.

- Coal Processing: Reducing coal size for energy production and industrial use.