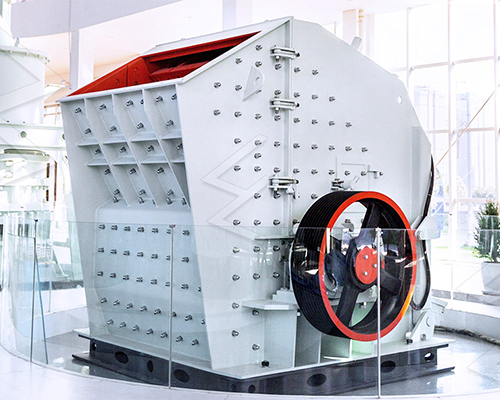

PFW Series Impact Crusher

Henan Liming Heavy Industry Science & Technology Co., Ltd., a pioneer in mining and aggregate processing solutions, introduces the PFW Series Impact Crusher—a state-of-the-art crushing machine engineered for superior performance in primary, secondary, and tertiary applications. Combining European-inspired design with robust construction, the PFW Series delivers exceptional efficiency, durability, and versatility, making it ideal for processing medium-hard to hard materials like granite, basalt, and concrete. Designed to maximize productivity while minimizing operational costs, this crusher exemplifies Liming’s commitment to innovation and customer-centric engineering.

Product Overview

The PFW Series Impact Crusher features a heavy-duty rotor, hydraulic adjustment system, and advanced wear-resistant components, ensuring reliable operation in the most demanding environments. Its unique “three-curtain” crushing chamber design enhances material reduction and produces uniformly shaped aggregates with minimal fines. Suitable for both stationary plants and mobile crushing stations, the PFW Series excels in quarrying, mining, recycling, and infrastructure projects, offering unmatched adaptability and ease of maintenance.

Key Features

- Heavy-Duty Rotor & Three-Curtain Design

- Reinforced rotor with high inertia ensures powerful impact force and stable operation.

- Three-stage crushing chamber optimizes material flow for higher reduction ratios and cubic-shaped output.

- Hydraulic Adjustment & Safety

- Hydraulic system allows quick adjustment of the discharge gap for precise control over output size.

- Automatic overload protection prevents damage from uncrushable materials.

- Enhanced Wear Resistance

- High-chrome alloy blow bars and impact plates withstand extreme abrasion.

- Modular design simplifies replacement of wear parts without dismantling the rotor.

- Low Operational Costs

- Energy-efficient motor reduces power consumption by up to 25%.

- Long service life of components minimizes downtime and maintenance expenses.

- User-Centric Design

- Openable frame structure provides easy access for inspection and maintenance.

- PLC-based automation (optional) enables real-time monitoring and remote control.

Processing Capacity & Materials

- Throughput: 70–1,500 tons per hour (model-dependent).

- Max Feed Size: Up to 1,000 mm.

- Adjustable Output Size: 10–80 mm (customizable to meet specific requirements).

- Materials Processed: Granite, basalt, limestone, concrete, construction waste, coal, and industrial minerals.

Applications

- Mining & Quarrying: Crushing ores and aggregates for mineral extraction and processing.

- Construction: Producing high-quality aggregates for roads, bridges, and building foundations.

- Recycling: Transforming demolition waste and concrete into reusable materials.

- Cement Production: Crushing raw materials and clinker for cement manufacturing.

- Railway & Highway Projects: Supplying uniform ballast and base materials.